Maximizing qPCR Efficiency with Challenging RNA Samples: A Guide to Robust Gene Expression Data

Obtaining reliable quantitative PCR (qPCR) results from low-quality or inhibitor-rich RNA samples is a common challenge in biomedical research and drug development.

Maximizing qPCR Efficiency with Challenging RNA Samples: A Guide to Robust Gene Expression Data

Abstract

Obtaining reliable quantitative PCR (qPCR) results from low-quality or inhibitor-rich RNA samples is a common challenge in biomedical research and drug development. This article provides a comprehensive framework for researchers to overcome these hurdles, covering the foundational principles of RNA integrity and PCR inhibition, methodological best practices for nucleic acid purification and assay design, systematic troubleshooting protocols, and rigorous validation strategies. By integrating current guidelines and advanced analytical approaches, this guide empowers scientists to enhance the rigor, reproducibility, and accuracy of their gene expression data, even when working with suboptimal sample material.

Understanding the Root Causes: RNA Degradation and PCR Inhibition

For researchers focused on improving qPCR efficiency with low-quality RNA samples, assessing RNA integrity is a critical first step. High-quality RNA is fundamental for reliable gene expression data, as compromised samples can significantly alter quantification results and lead to erroneous conclusions. This guide provides a comprehensive overview of the key metrics, tools, and troubleshooting methods essential for evaluating and ensuring RNA quality in your qPCR workflows.

Key Metrics for Assessing RNA Quality

RNA quality can be systematically evaluated using several key parameters. The table below summarizes the primary metrics used for assessment.

| Metric | Description | Target Values | Indication of Problem |

|---|---|---|---|

| A260/A280 Ratio | Purity check for protein contamination [1] | 1.8 - 2.0 [1] [2] | Ratio < 1.8 suggests significant protein contamination [2] [1]. |

| A260/A230 Ratio | Purity check for contaminants like salts or organics [1] | > 1.7 [1] | Ratio < 1.7 indicates carryover of guanidine salts, ethanol, or other inhibitors [3] [4]. |

| RNA Integrity Number (RIN) | Electropherogram-based score for RNA degradation; scale of 1 (degraded) to 10 (intact) [1] | ≥ 7 (application-dependent) | A low RIN indicates generalized RNA degradation. |

| 28S:18S rRNA Ratio | Visual assessment of ribosomal RNA bands on a gel [1] | ~2:1 for mammalian RNA [1] | Band smearing or a ratio inversion (18S > 28S) indicates degradation [1] [4]. |

| Concentration | Quantity of RNA, measured via absorbance or fluorescent dyes [1] | Application-dependent | Low yield can point to incomplete homogenization, insufficient elution, or degradation [3] [4]. |

| gDNA Contamination | Presence of genomic DNA | Not detectable | Amplification in no-RT control qPCR assays [4]. |

RNA Quality Assessment Tools and Methods

Different tools offer varying levels of information about your RNA sample, from simple concentration checks to a full integrity profile.

| Tool/Method | Principle | Information Provided | Advantages | Disadvantages |

|---|---|---|---|---|

| UV Spectrophotometry (NanoDrop) [1] | Measures absorbance of UV light at 260nm, 280nm, and 230nm. | Concentration, A260/A280 and A260/A230 ratios. | Fast; small sample volume (0.5-2 µl); wide detection range [1]. | Cannot detect RNA degradation or gDNA contamination; overestimation if contaminants absorb at 260nm [1]. |

| Fluorescent Dye-Based (Quantus, Qubit) [1] | Fluorescent dye binds RNA; fluorescence is measured. | Highly accurate RNA concentration. | Very sensitive (can detect as low as 1 pg/µl); more specific for RNA than absorbance (if combined with DNase) [1]. | Does not provide purity or integrity data; requires standard curves; dyes can be hazardous [1]. |

| Agarose Gel Electrophoresis [1] | Separates RNA fragments by size using an electric current. | Integrity (sharp rRNA bands), 28S:18S ratio, gDNA contamination (high molecular weight smear). | Low cost; qualitative integrity assessment; visualizes gDNA [1]. | Semi-quantitative; requires more RNA; hands-on time; toxic dyes (e.g., ethidium bromide) [1]. |

| Microfluidics Platform (Bioanalyzer, TapeStation) [1] | Microfluidic capillary electrophoresis separates RNA fragments. | RIN, concentration, integrity profile, digital gel image. | "Gold standard"; small sample size; objective integrity score (RIN); high sensitivity [1]. | Higher cost; specialized equipment. |

RNA QC Workflow

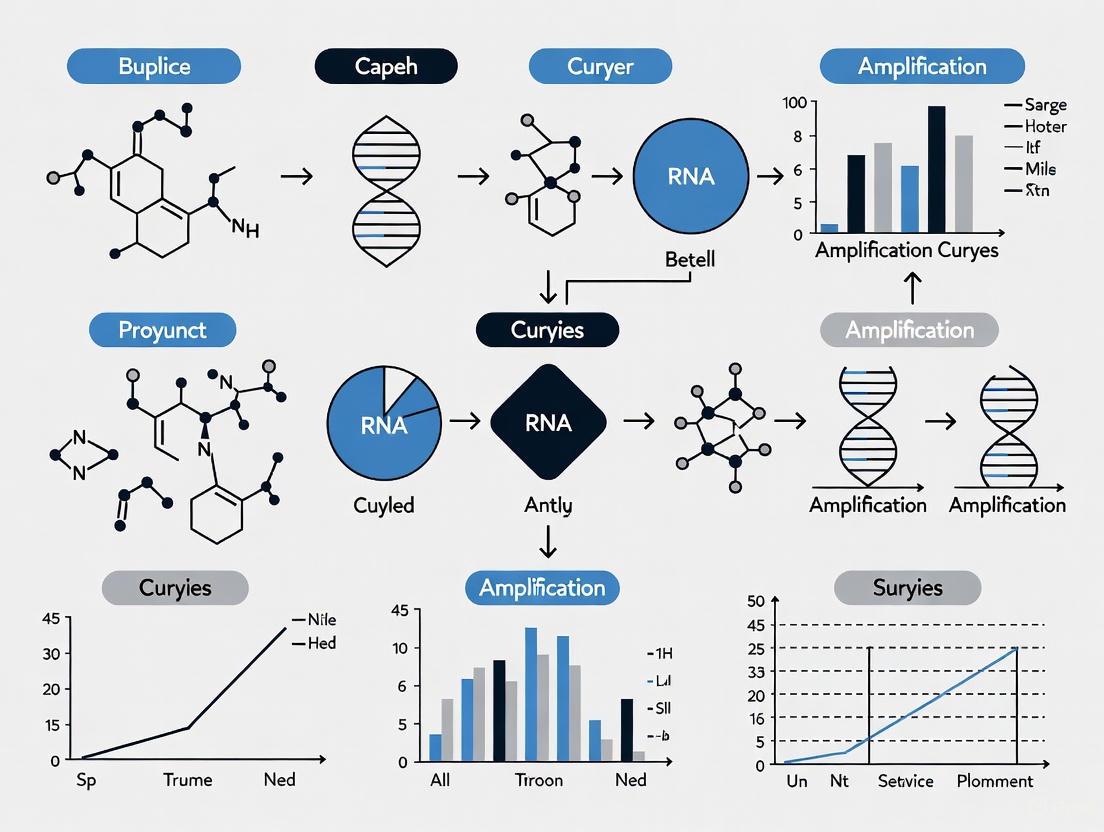

The following diagram illustrates a logical workflow for assessing RNA quality, from initial measurement to interpretation of results for downstream applications like qPCR.

The Scientist's Toolkit: Essential Reagents & Materials

| Item | Function |

|---|---|

| DNase I Enzyme | Digests and removes contaminating genomic DNA from the RNA preparation, preventing false positives in qPCR [3] [4]. |

| RNase Inhibitors (e.g., BME) | Added to lysis buffers to inactivate RNases and preserve RNA integrity during the isolation process [4]. |

| RNA Preservation Reagents (e.g., RNALater) | Stabilizes and protects RNA in tissues or cells immediately after collection, preventing degradation prior to extraction [3] [4]. |

| Acidic Phenol (pH 4-5) | Used in liquid-phase separation methods (e.g., TRIzol) to denature proteins and separate RNA into the aqueous phase while leaving DNA in the interphase [4]. |

| Silica Spin Columns | Bind RNA in the presence of high-salt buffers, allowing for impurities to be washed away and pure RNA to be eluted [3] [4]. |

| Guanidine-based Lysis Buffers | Powerful chaotropic agents that inactivate RNases, denature proteins, and facilitate binding of RNA to silica columns [3] [4]. |

Frequently Asked Questions

My RNA has a low A260/A230 ratio. What does this mean and how can I fix it?

A low A260/A230 ratio (typically below 1.7) indicates carryover of contaminants such as guanidine salts from the isolation kit, ethanol, or carbohydrates [3] [1] [4].

- Solution: Perform additional wash steps with 70-80% ethanol if using a silica column [4]. For RNA already in solution, an ethanol precipitation can effectively desalt the sample [4].

My RNA yield is low, but the quality seems intact. What could be the cause?

Low yields with good integrity often point to incomplete homogenization or lysis, meaning the RNA was not fully released from the cells [3] [4]. Alternatively, using too little starting material or failing to elute the RNA from the column membrane in a sufficient volume can also cause this [4].

- Solution: Optimize your homogenization protocol to ensure complete tissue disruption. For column-based kits, use the maximum recommended elution volume to maximize recovery [4].

How does RNA quality specifically affect qPCR efficiency?

Poor RNA quality is a major source of error in qPCR.

- Inhibitors: Contaminants that co-purify with RNA (evidenced by low A260/A230) can inhibit the reverse transcriptase and DNA polymerase enzymes. This leads to higher Ct values, reduced sensitivity, and in dilution series, can cause a flattening of the standard curve slope, resulting in calculated efficiencies that exceed 100% [5].

- Degradation: Partially degraded RNA provides less full-length template for reverse transcription, preferentially reducing the signal for longer transcripts and introducing bias in gene expression measurements [1].

My no-RT control shows amplification, suggesting gDNA contamination. How do I remove it?

Genomic DNA contamination is a common issue that can lead to false-positive results in qPCR [4].

- Solution: The most reliable method is to treat your purified RNA with a DNase I enzyme. This can be performed "on-column" during the purification of some kits, or in-tube after the RNA has been eluted [3] [4]. Always include a no-RT control in your qPCR setup to detect gDNA contamination.

My RNA is degraded. How can I prevent this in the future?

Degradation occurs when RNases are activated.

- Solution: Flash-freeze tissues immediately after collection or preserve them in RNALater [4]. During extraction, ensure samples are fully homogenized in a denaturing lysis buffer (e.g., containing guanidine) and add beta-mercaptoethanol (BME) to inactivate RNases [4]. Always use RNase-free tips, tubes, and water.

PCR inhibitors can originate from the sample itself, reagents used during preparation, or the sample's environment. They interfere with the PCR reaction by affecting the DNA polymerase, interacting with the nucleic acids, or quenching the fluorescent signal [6] [7].

The table below summarizes common inhibitor sources and their mechanisms of action:

| Source Category | Specific Examples | Primary Mechanism of Inhibition |

|---|---|---|

| Biological Samples | Hemoglobin (blood), heparin (plasma), immunoglobulins, lactoferrin [2] [6] | Polymerase inhibition, co-factor chelation [7] |

| Environmental Samples | Humic acids, fulvic acids (soil, water), tannins, melanin [2] [6] | Interaction with nucleic acids, fluorescence quenching [6] [8] |

| Sample Prep Reagents | SDS, phenol, ethanol, guanidinium, sodium acetate, proteinase K [2] [9] | Disruption of primer binding, polymerase inhibition [2] [7] |

| Complex Polysaccharides | Polysaccharides (plants, feces) [2] [8] | Polymerase inhibition, nucleic acid sequestration [8] |

How can I detect the presence of PCR inhibitors in my samples?

Several experimental indicators can signal the presence of PCR inhibitors. You can monitor these during your qPCR run or through specific control experiments [2] [7].

Key Indicators of Inhibition:

- Delayed Cq Values: A general increase in Cq values across all samples, including positive controls, suggests inhibition. Using an Internal PCR Control (IPC) is crucial here; if the IPC is also delayed, inhibition is likely [7].

- Poor Amplification Efficiency: In a standard curve experiment (e.g., a 10-fold dilution series), the calculated PCR efficiency should ideally be between 90% and 100% (slope between -3.6 and -3.3). A slope steeper than -3.3 (efficiency >100%) can indicate inhibition in concentrated samples, while a shallower slope (efficiency <90%) indicates general poor efficiency [2] [5].

- Abnormal Amplification Curves: Flattened curves, a lack of clear exponential growth phase, or a failure to cross the detection threshold can all point to inhibition affecting enzyme activity or fluorescence [7].

- Inhibition Plot Analysis: In a standard curve, if the most concentrated sample point has a later Cq than expected but the curve normalizes with dilution, this indicates that inhibitors are being diluted out. This pattern can lead to an apparent efficiency of over 100% [2] [5].

Experimental Protocol: Using a Dilution Series to Detect Inhibition

- Prepare Template: Create a serial dilution (e.g., 1:10 dilutions) of your sample DNA or cDNA.

- Run qPCR: Amplify all dilution points in replicate using your target assay.

- Analyze Data: Generate a standard curve from the Cq values.

- Interpret Results:

- No Inhibition: The Cq values for the dilution series will be approximately 3.3 cycles apart, and the standard curve will be linear across all points [2].

- With Inhibition: The ΔCq between the most concentrated samples will be less than 3.3 (e.g., 2.8), but will approach 3.3 in the more diluted samples where the inhibitor concentration is negligible. This flattens the standard curve and can cause calculated efficiency to exceed 100% [2] [5].

What practical strategies can I use to overcome PCR inhibition?

Overcoming inhibition often requires a multi-faceted approach, from improving sample purification to optimizing the reaction itself.

Detailed Strategies:

Enhance Sample Purification:

- High-Quality Kits: Use isolation kits specifically designed for your sample type (e.g., soil, blood, plants) to maximize inhibitor removal [2] [7].

- Additional Purification: For contaminated RNA (low A260/A280 ratio), further purify by phenol-chloroform extraction, LiCl precipitation, or salt washes [2] [9].

- Template Dilution: Diluting the nucleic acid template also dilutes the inhibitor. Test to find a concentration where inhibition is minimized but the target remains detectable [2] [7].

Optimize qPCR Reaction Conditions:

- PCR Enhancers: Add compounds like Bovine Serum Albumin (BSA) or T4 gene 32 protein (gp32), which can bind to inhibitors like humic acids. Other enhancers include DMSO, formamide, Tween-20, and glycerol, which can help destabilize secondary structures or stabilize enzymes [8] [7].

- MgCl₂ Adjustment: Increase Mg²⁺ concentration to counteract chelators like heparin or EDTA that sequester essential co-factors [7].

- Hot-Start Polymerases: These enzymes increase specificity and reduce primer-dimer formation, which is beneficial in suboptimal conditions [7].

Select Inhibitor-Resistant Reagents:

How does genomic DNA contamination act as an inhibitor, and how is it removed?

Genomic DNA (gDNA) in RNA samples is a significant concern for qRT-PCR. It can lead to false positive results and inaccurate quantification by providing a non-target template for amplification [9].

Removal and Prevention Strategies:

- DNase I Treatment: This is the most effective method for removing gDNA contamination. Treatment can be performed on purified RNA samples or, in some kits, directly on the lysate. It is critical to properly inactivate or remove the enzyme after treatment to prevent RNA degradation [9].

- Acid Phenol:Chloroform Extraction or LiCl Precipitation: These are alternative purification methods that can help remove gDNA [9].

- Use of Intron-Spanning Assays: Design primers and probes to span an exon-exon junction. This ensures that amplification only occurs from spliced cDNA and not from gDNA. In TaqMan assays, look for "_m1" suffixes which indicate the probe spans a junction [9].

- No-Reverse Transcription Control (-RT Control): Always include a control that contains all reaction components except the reverse transcriptase. Amplification in this control indicates gDNA contamination [9] [10].

Research Reagent Solutions

The table below lists key reagents and kits mentioned in the literature for tackling PCR inhibition and improving results with challenging samples.

| Reagent / Kit | Primary Function | Key Application |

|---|---|---|

| DNase I (e.g., TURBO DNA-free kit) | Enzymatic degradation of genomic DNA contaminating RNA samples. | Essential for accurate qRT-PCR; prevents false positives from gDNA amplification [9]. |

| Inhibitor-Resistant Master Mix (e.g., GoTaq Endure) | qPCR master mix formulated with specialized polymerases and buffers for high inhibitor tolerance. | Reliable amplification from difficult samples like blood, soil, and plant extracts [7]. |

| PCR Enhancers (BSA, gp32, DMSO) | Additives that bind inhibitors, destabilize secondary structures, or stabilize enzymes. | Counteract specific inhibitors like humic acids (BSA/gp32) or improve amplification efficiency in suboptimal conditions [8]. |

| Sample Purification Kits (e.g., PureLink, MagMAX) | Silica-column or magnetic bead-based nucleic acid purification. | High-quality RNA/DNA isolation with built-in DNase treatment steps to minimize carryover of inhibitors and gDNA [9]. |

| Cells-to-CT Kits | Lysis-based preparation from cultured cells without a separate RNA purification step. | Rapid preparation (minutes) with integrated DNase I digestion, suitable for high-throughput screening [9]. |

| Uracil-N-Glycosylase (UNG) | Enzyme that degrades uracil-containing DNA from previous PCR amplifications. | Prevents false positives from amplicon carryover contamination; used as a pre-PCR step [10]. |

How Inhibitors and Degradation Skew Amplification Efficiency

Troubleshooting Guides

Frequently Asked Questions

1. What are the common indicators that my qPCR reaction is inhibited? You can identify potential inhibition through several key signs in your amplification data:

- Delayed Cq Values: A general increase in Cq values across all samples and controls suggests inhibition. This can be confirmed using an Internal PCR Control (IPC); if the IPC's Cq is also delayed, inhibition is likely [7].

- Poor Amplification Efficiency: The calculated efficiency of your assay falls outside the acceptable range of 90–110% (standard curve slope between -3.1 and -3.6). A shallower slope indicates poor efficiency [7] [2].

- Abnormal Amplification Curves: Flattened curves, a lack of a distinct exponential phase, or a failure to cross the detection threshold can signal interference with the polymerase or fluorescence detection [7].

- Efficiency Exceeding 100%: While less intuitive, calculated efficiency over 110% can also indicate inhibition. Inhibitors present in more concentrated samples prevent optimal amplification, flattening the standard curve slope and artificially inflating the efficiency value [5].

2. My RNA is degraded. How does this differ from inhibition in its effect on qPCR? Inhibition and degradation impact the reaction at different stages and present distinct profiles:

- RNA Degradation affects the starting material. It reduces the number of intact template molecules available for reverse transcription and amplification. This typically results in higher Cq values and a lower final signal, but the amplification efficiency itself often remains within the acceptable range because the remaining intact templates amplify correctly.

- Inhibition affects the amplification process. Inhibitory substances interfere with the enzyme's activity during the reaction, leading to reduced amplification efficiency and potentially abnormal curve shapes, even if the starting template is intact.

3. Are some sample types more prone to inhibitors than others? Yes, certain complex sample matrices are well-known sources of PCR inhibitors. The table below summarizes common inhibitors and their effects [7] [6].

Table 1: Common Sources of qPCR Inhibitors and Their Effects

| Source | Example Inhibitors | Primary Effect on qPCR |

|---|---|---|

| Biological Samples | Hemoglobin (blood), Heparin (plasma), Immunoglobulin G (serum) | Polymerase inhibition, co-factor chelation [7] [6] |

| Environmental Samples | Humic acids (soil, water), Phenols (water), Tannins (plants) | DNA degradation, fluorescence interference, polymerase inhibition [7] [6] [11] |

| Laboratory Reagents | SDS, Ethanol, Guanidinium, Sodium Acetate (from extraction) | Template precipitation, primer binding disruption, enzyme inhibition [7] [2] |

4. What strategies can I use to overcome inhibition in my low-quality RNA samples? A multi-faceted approach is often most successful:

- Optimize Sample Purification: Use high-quality RNA extraction kits designed for your sample type. Perform additional clean-up steps (e.g., column-based purification, ethanol precipitation) or use polymeric adsorbents like DAX-8 to remove humic acids [7] [11].

- * dilute the Template:* Diluting the nucleic acid extract can reduce the concentration of inhibitors to a non-inhibitory level. Be cautious, as this also dilutes the target and may push low-abundance targets below the detection limit [7] [8].

- Use Inhibitor-Tolerant Reagents: Select a qPCR master mix specifically formulated for high inhibitor tolerance. These often contain specialized polymerase blends and buffer components [7].

- Employ PCR Enhancers: Adding compounds like Bovine Serum Albumin (BSA) or T4 gene 32 protein (gp32) can bind to inhibitors and stabilize the polymerase reaction [8].

Guide to Diagnosing and Solving Inhibition

Problem: Suspected PCR inhibition in my RNA samples from complex matrices (e.g., soil, wastewater, blood).

Objective: To confirm the presence of inhibitors and implement an effective strategy to mitigate their effects, thereby restoring accurate amplification efficiency.

Experimental Protocol 1: Detecting Inhibition using an Internal Control

This method helps distinguish between true inhibition and simply low template concentration [12].

- Spike your sample with a known, moderate amount of a control RNA or DNA sequence (the Internal Amplification Control, IAC) that is not related to your target.

- Perform two qPCR reactions:

- Reaction A: Your sample RNA + primers for your target gene.

- Reaction B: Your sample RNA + primers for the IAC.

- Run a parallel control: Perform qPCR for the IAC in a clean, inhibitor-free solution.

- Interpretation: Compare the Cq value of the IAC in the sample (Reaction B) to the Cq value of the IAC in the clean control. A significant delay (e.g., > 2 cycles) in the sample indicates the presence of inhibitors affecting the reaction [12].

Experimental Protocol 2: Using a Standard Curve to Calculate Efficiency

This is a fundamental diagnostic to assess the overall health of your qPCR assay [2] [13].

- Preparation: Create a serial dilution (e.g., 1:10 or 1:4 dilutions) of a control template RNA. Use at least 5 dilution points for a reliable curve.

- qPCR Run: Amplify each dilution in duplicate or triplicate using your target assay.

- Data Analysis: The qPCR software will plot the Cq values against the logarithm of the starting concentration and generate a trendline.

- Calculate the slope of the standard curve.

- Calculate efficiency using the formula: Efficiency (%) = [10^(-1/slope) - 1] x 100.

- Interpretation:

- Ideal: Slope = -3.32, Efficiency = 100% (perfect doubling every cycle).

- Acceptable: Efficiency between 90% and 110% [2].

- Poor Efficiency: Efficiency < 90% indicates inhibition or suboptimal reaction conditions.

- Artificially High Efficiency: Efficiency > 110% can suggest inhibition in the more concentrated samples of your standard curve [5].

The following diagram illustrates the core concepts of how inhibitors and degradation impact the qPCR reaction and how to diagnose them.

Diagram 1: Diagnostic flowchart for inhibition versus degradation.

The Scientist's Toolkit: Research Reagent Solutions

This table lists key reagents and materials used to prevent and overcome qPCR inhibition.

Table 2: Essential Reagents for Managing qPCR Inhibition

| Reagent/Material | Function & Mechanism | Example Use Cases |

|---|---|---|

| Inhibitor-Tolerant Master Mix | Contains specialized polymerase enzymes (often blends) and optimized buffers that are resistant to a wide range of inhibitors. | GoTaq Endure qPCR Master Mix is designed for challenging samples like blood, soil, and plants [7]. |

| Bovine Serum Albumin (BSA) | Acts as a "molecular sponge," binding to inhibitors like phenols and humic acids, preventing them from interfering with the polymerase. | Adding BSA to the reaction is a common strategy for environmental samples (soil, wastewater) and blood-derived samples [7] [8]. |

| Polymeric Adsorbents (e.g., DAX-8) | Insoluble polymers that permanently bind to and remove inhibitory substances like humic acids from nucleic acid extracts prior to qPCR. | Treatment with 5% DAX-8 was shown to significantly improve viral detection in complex river water samples [11]. |

| T4 Gene 32 Protein (gp32) | A single-stranded DNA-binding protein that stabilizes DNA and can prevent the action of inhibitors on the DNA polymerase. | Effective for counteracting inhibition in various sample types, including wastewater [8]. |

| PCR Enhancers (DMSO, Betaine) | Reduce secondary structures in DNA/RNA by lowering melting temperature, improving primer annealing and polymerase processivity. | Useful for amplifying GC-rich targets or templates with complex secondary structures [8]. |

| Internal Amplification Control (IAC) | A non-target nucleic acid sequence spiked into the reaction to monitor for inhibition. A shift in its Cq indicates inhibition. | Essential for diagnostic assays and any qPCR experiment where false negatives due to inhibition are a concern [7] [12]. |

Interpreting Spectrophotometer and Bioanalyzer Results for Quality Control

For researchers focusing on improving qPCR efficiency with low-quality RNA samples, robust quality control (QC) is the critical first step. The integrity and purity of your RNA template directly dictate the success and reliability of downstream quantitative PCR (qPCR) [2]. This guide provides troubleshooting support for the two cornerstone instruments of RNA QC: the spectrophotometer and the bioanalyzer. Ensuring accurate results from these tools is fundamental to diagnosing issues with PCR efficiency and achieving rigorous, reproducible gene expression data [14].

Frequently Asked Questions (FAQs)

Q1: What do my spectrophotometer RNA purity ratios (A260/A230 and A260/A280) actually mean for my experiment?

The absorbance ratios measured by a spectrophotometer are primary indicators of sample purity, which directly impacts enzymatic reactions like reverse transcription and PCR.

- A260/A280 Ratio: This assesses protein contamination. A high-quality RNA sample should have a ratio of approximately 2.0 [2]. A ratio significantly lower than this (e.g., 1.8 or below) suggests residual protein presence. It has been observed that an A260/A280 reading of 1.8 indicates that about 70–80% of the sample may be protein, which can inhibit both reverse transcription and PCR [2].

- A260/A230 Ratio: This assesses contamination from organic compounds, such as salts, EDTA, or carbohydrates. This ratio should be greater than 2.0 for a pure RNA sample. A lower value indicates the presence of contaminants that can inhibit polymerase enzymes.

Q2: Why is my qPCR efficiency poor even with acceptable spectrophotometer ratios?

Acceptable purity ratios do not guarantee the absence of PCR inhibitors or the structural integrity of the RNA. Spectrophotometer ratios are a useful first pass but provide an average measurement across all nucleic acids in a sample and cannot distinguish between intact and degraded RNA, or identify specific inhibitors that fall below their detection threshold [2] [5]. This is why a multi-modal QC approach is essential.

- Inhibitors Not Detected by Spectrophotometry: Your sample may contain PCR inhibitors that do not significantly alter the A260/A280 ratio. Common inhibitors include heparin, hemoglobin, polysaccharides, ethanol, phenol, SDS, and guanidinium [2] [5].

- RNA Integrity Issues: Spectrophotometry cannot determine RNA integrity. Degraded RNA, even if pure, will yield poor and variable qPCR results. This is where the bioanalyzer provides critical additional information.

- Solution: Further purify your RNA samples using phenol-chloroform extraction or LiCl precipitation if purity ratios are low [2]. For degraded samples, start with higher quality input material or use a master mix tolerant of lower quality RNA.

Q3: My bioanalyzer electropherogram shows a broad peak or a smear. What does this indicate?

A clean RNA sample on a bioanalyzer will show sharp, distinct ribosomal RNA peaks (18S and 28S for eukaryotic RNA) with a baseline that runs flat between them. Deviations from this ideal profile indicate specific problems:

- A Smear Below the Ribosomal Peaks: This indicates RNA degradation. The smear consists of fragmented RNA molecules of various sizes. Degraded RNA is a common cause of low qPCR yield and inconsistent Cq values.

- A Broad Peak or Shouldering: This can indicate the presence of genomic DNA contamination, especially if the broad peak is present at higher molecular sizes.

- A Shift in Peak Sizes: This could indicate a problem with the sample buffer or the bioanalyzer ladder itself, and the run should be repeated with fresh reagents.

Troubleshooting Guides

Spectrophotometer Troubleshooting

Many QC issues can be prevented by following foundational best practices: allow the instrument to warm up for 15-30 minutes, always handle cuvettes by their sides and wipe them with a lint-free cloth, use the correct cuvette type (quartz for UV measurements), and prepare a proper blank with the exact same solvent as your sample [15].

The table below outlines common problems and their solutions.

| Problem | Possible Cause | Solution |

|---|---|---|

| Unstable or Drifting Readings | Instrument lamp not stabilized; air bubbles in sample; environmental vibrations [15]. | Allow 15-30 min warm-up; tap cuvette to dislodge bubbles; place instrument on stable surface [15]. |

| Cannot Set to 100% Transmittance (Fails to Blank) | Aging light source; dirty or misaligned optics; cuvette holder not seated properly [15]. | Check/replace lamp; ensure holder is secure; service instrument if optics are dirty [15]. |

| Negative Absorbance Readings | Blank solution is "dirtier" than sample; using different cuvettes for blank and sample [15]. | Use the same cuvette for blank and sample; ensure cuvette is clean before blanking [15]. |

| Inconsistent Replicate Readings | Cuvette orientation not consistent; sample is evaporating or degrading [15]. | Always place cuvette in same orientation; minimize time between measurements [15]. |

| Absorbance Reading Nonlinear Above 1.0 | Sample is too concentrated, pushing beyond the instrument's linear detection range [16]. | Dilute your sample to bring the absorbance reading into the optimal 0.1-1.0 range [16]. |

Bioanalyzer Troubleshooting

The bioanalyzer (and similar fragment analyzers) provides a capillary electrophoresis-based assessment of RNA integrity, which is crucial for interpreting qPCR performance.

| Problem | Possible Cause | Solution |

|---|---|---|

| No peaks or very low signal | RNA concentration too low; improper pipetting during chip priming or loading; degraded RNA. | Check RNA concentration with spectrophotometer; practice precise pipetting technique; use a new, high-quality RNA sample. |

| Unexpected peaks or ladder anomalies | Contamination with genomic DNA or other nucleic acids; degraded RNA ladder; improper storage of reagents. | Treat RNA samples with DNase I; use a fresh aliquot of ladder and ensure all reagents are stored correctly. |

| High background noise | Contaminated electrodes; old or improperly stored reagents; debris in the sample. | Clean the instrument's electrodes according to manufacturer's instructions; use fresh reagents; filter the sample if necessary. |

The Link Between QC Metrics and qPCR Efficiency

The ultimate goal of RNA QC is to ensure accurate and efficient qPCR results. The quality of your input RNA has a direct and profound impact on PCR efficiency.

- The Gold Standard: An optimal qPCR reaction has an efficiency between 90% and 110%, which corresponds to a slope of -3.6 to -3.3 on a standard curve [2] [17]. This means the amount of PCR product nearly doubles with each cycle.

- Poor Efficiency (Slope < -3.6): This is often caused by the presence of PCR inhibitors identified in poor QC metrics, suboptimal primer/probe design, or inaccurate pipetting [2].

- Efficiency > 100% (Slope > -3.3): This can be a less intuitive problem. It is frequently caused by PCR inhibition in your more concentrated samples [2] [5]. The inhibitors are diluted out in your standard curve's lower concentration points, making the curve flatter and the calculated efficiency artificially high. Other causes include pipetting errors during serial dilution or the presence of primer dimers [5].

The following workflow diagram illustrates the logical relationship between QC results, their potential causes, and the downstream effects on qPCR.

Research Reagent Solutions

The following table details key reagents and materials essential for effective RNA quality control and subsequent qPCR optimization.

| Item | Function in QC/qPCR |

|---|---|

| Quartz Cuvettes | Essential for accurate UV spectrophotometry measurements below 340 nm, as plastic and glass absorb UV light [15]. |

| RNA Isolation Kits | Specialized kits (e.g., column-based, TRIzol) for purifying RNA from specific sample types (tissue, cells, FFPE), crucial for removing inhibitors [2]. |

| DNase I | Enzyme used to digest contaminating genomic DNA during RNA purification, preventing false positives in qPCR [17]. |

| qPCR Master Mix | Pre-mixed solutions containing DNA polymerase, dNTPs, buffer, and salts. Some master mixes are formulated to be more tolerant of common PCR inhibitors found in complex samples [5]. |

| Universal RNA Standards | Exogenous control RNAs (e.g., from the ERCC) used to evaluate the performance and compare the accuracy of different RT-qPCR platforms and protocols [18]. |

| TaqMan Assays | Optimized primer and probe sets for specific gene targets, designed using bioinformatic tools to ensure specificity and avoid regions like SNPs or low-complexity sequences [2]. |

Interpreting spectrophotometer and bioanalyzer results is not a mere formality but a critical diagnostic step in any qPCR workflow, especially when working with challenging low-quality RNA samples. A comprehensive QC strategy that integrates both purity and integrity assessments allows researchers to proactively identify issues, select the appropriate remediation strategy—be it further purification, protocol optimization, or reagent selection—and ultimately lay the foundation for precise and reliable gene expression data.

Proactive Strategies: From Sample Prep to Assay Design

Selecting the Right RNA Isolation Kit for Your Sample Type

For researchers focused on improving qPCR efficiency with low-quality RNA samples, selecting the appropriate RNA isolation method is a critical first step. The integrity and purity of your isolated RNA directly impact downstream qPCR results, including amplification efficiency, quantification cycle (Cq) values, and overall assay reliability [19]. This guide provides comprehensive technical support to help you navigate kit selection and troubleshoot common RNA extraction challenges.

Understanding RNA Isolation Methods

RNA isolation utilizes various technological approaches to separate RNA from other cellular components. Understanding these core methodologies helps in selecting the most appropriate technique for your specific application.

Table: Comparison of Major RNA Isolation Techniques

| Method | Principle | Best For | Advantages | Limitations |

|---|---|---|---|---|

| Organic Extraction [20] [21] | Phenol-chloroform phase separation; RNA partitions to aqueous phase | Difficult samples (high lipid, nuclease-rich), scalable input [21] | Robust, effective nuclease denaturation, broad sample compatibility [21] | Toxic reagents, labor-intensive, difficult to automate [20] |

| Spin Column (Silica Membrane) [20] [21] | RNA binding to silica membrane in presence of chaotropic salts; wash and elute | Most sample types, low to medium throughput [21] | Easy, familiar format, cost-effective, amenable to 96-well processing [20] | Membrane clogging with particulates, fixed binding capacity [20] |

| Magnetic Beads [20] [21] | Paramagnetic particles with RNA-binding surfaces capture RNA from solution | High throughput, automated workflows, inhibitor-prone samples [21] | No clogging, efficient solution-based binding, automation-friendly [20] | Potential bead carryover, slow migration in viscous solutions [20] |

| Direct Lysis [20] [21] | Chemical lysis without purification; stabilized lysate used directly | Extremely fast processing, very small samples, high-throughput screening [20] [21] | Fastest method, avoids binding/elution bias, simple automation [20] | Cannot spectrophotometrically quantify, potential residual RNase activity [20] |

Kit Selection Guide by Sample Type

Different sample types present unique challenges for RNA isolation. The table below outlines common sample-specific issues and recommended solutions to ensure high-quality RNA extraction.

Table: Sample-Specific RNA Isolation Challenges and Solutions

| Sample Type | Common Challenges | Recommended Solutions | Special Considerations |

|---|---|---|---|

| Tissues [22] [20] | RNase activity, variable cellularity, degradation during collection | Immediate stabilization with RNAlater solution [20], thorough homogenization, increased protease treatment [23] | Flash-freeze in liquid nitrogen or use specialized stabilization reagents [20] |

| Whole Blood [22] [7] | High RNase activity, PCR inhibitors (hemoglobin, heparin), low RNA yield | Use specialized blood RNA kits, additional inhibitor removal steps [7], proper anticoagulant selection | Consider nucleated cell enrichment for certain applications |

| Plant Tissues [22] [7] | Polysaccharides, polyphenols, pigments, cell walls | CTAB-based extraction, extensive washing, polyvinylpyrrolidone to bind phenols | Homogenize under liquid nitrogen; may require additional purification |

| Cultured Cells [22] [21] | Rapid RNA degradation, variable cell numbers | Direct lysis in culture dish, use of RNA stabilization reagents | Count cells for consistent input; avoid overgrowth |

| Bacteria/Yeast [21] [19] | Tough cell walls, high RNase activity | Enzymatic lysis (lysozyme, zymolase), bead beating, hot phenol | Use specialized kits with rigorous mechanical disruption |

| FFPE Tissues [19] | RNA cross-linking, fragmentation, chemical modifications | Extended protease digestion, specialized de-crosslinking solutions, RNA repair enzymes | Expect shorter RNA fragments; quality assessment is critical |

Troubleshooting Common RNA Extraction Problems

Low RNA Yield

Problem: Insufficient RNA quantity for downstream applications.

Causes and Solutions:

- Incomplete cell/tissue disruption: Increase homogenization time or intensity; use larger volumes of lysis buffer [23]

- Incomplete elution: Ensure elution buffer is applied directly to the membrane center; incubate 5-10 minutes before centrifugation; perform second elution [24] [23]

- Excessive sample input: Reduce starting material to match kit specifications [23]

- RNA secondary structure: For small RNAs (<45 nt), dilute sample with 2 volumes of ethanol instead of 1 volume [24]

RNA Degradation

Problem: Degraded RNA showing smeared electrophoresis pattern or poor 28S/18S rRNA ratio.

Causes and Solutions:

- RNase contamination: Work in clean area with RNase-free tips and tubes; wear gloves; keep kit components tightly sealed [24]

- Improper sample storage: Store input samples at -80°C; use RNA stabilization reagents (e.g., DNA/RNA Protection Reagent) during storage [23]

- Slow processing: Process samples quickly after collection; use immediate stabilization methods [20]

DNA Contamination

Problem: Genomic DNA contamination interfering with downstream applications.

Solutions:

- Perform on-column DNase I treatment during purification [24] [23]

- For severe contamination, perform in-tube/off-column DNase I treatment followed by RNA cleanup [24] [23]

- Reduce starting material to prevent column overloading [23]

Poor Purity (Low A260/230 and A260/280 Ratios)

Problem: Contaminants affecting spectrophotometric measurements and downstream applications.

Causes and Solutions:

- Residual guanidine salts (low A260/230): Ensure complete wash steps; avoid column contact with flow-through; blot collection tube rims before reuse [24] [23]

- Residual protein (low A260/280): Ensure complete Proteinase K digestion; remove debris before loading onto column [23]

- Ethanol carryover: Extend final wash spin time to 2 minutes; add additional wash step if needed [23]

Connecting RNA Quality to qPCR Efficiency

RNA quality directly impacts qPCR results. Understanding this relationship is essential for obtaining reliable gene expression data, particularly when working with challenging samples.

How RNA Quality Affects qPCR

- Inhibitors in qPCR: Residual contaminants from extraction (ethanol, salts, phenol, SDS, guanidine) can inhibit polymerase activity, leading to delayed Cq values, reduced efficiency, or reaction failure [5] [7]

- Amplification efficiency >100%: This unexpected result often indicates polymerase inhibition in concentrated samples, where inhibitors flatten the standard curve slope [5]

- Degraded RNA: Results in inconsistent reverse transcription, underrepresentation of target sequences, and variable Cq values

Strategies to Overcome qPCR Inhibition

- Enhanced sample purification: Use high-quality extraction kits; perform additional clean-up steps; dilute template to reduce inhibitor concentration [7]

- Reaction optimization: Add BSA or trehalose to stabilize enzymes; adjust MgCl₂ concentration; use inhibitor-resistant polymerases [7]

- Quality assessment: Check RNA purity (A260/280 ratio >2.0 for RNA); analyze RNA integrity number (RIN) or 28S/18S ratio; use internal PCR controls [7]

Frequently Asked Questions (FAQs)

Q1: How do I choose between spin column and magnetic bead purification for high-throughput applications? Magnetic bead systems are generally preferred for high-throughput workflows as they're more easily automated, avoid filter clogging issues, and provide solution-based binding kinetics for more consistent results [20]. Spin columns may be more cost-effective for lower throughput applications.

Q2: What specific steps can I take when extracting RNA from difficult samples like fatty tissues or plants? For difficult samples, consider these approaches:

- Use organic extraction methods (e.g., TRIzol) for superior disruption and nuclease inhibition [21]

- Increase homogenization intensity and duration

- Add additional purification steps or specialized wash buffers

- For plants, use kits specifically designed for challenging plant materials [19]

Q3: My RNA appears intact but consistently fails in qPCR. What could be wrong? This often indicates carryover of inhibitors not detected by standard quality checks:

- Perform a 1:2 or 1:5 dilution of your RNA to reduce inhibitor concentration [7]

- Use a qPCR master mix designed for inhibitor tolerance [7]

- Check for residual salts or ethanol with additional wash steps [23]

- Test with an internal PCR control to distinguish between inhibition and target absence [7]

Q4: How long can I store purified RNA before degradation affects qPCR results? For best results in sensitive applications like qPCR:

- Store RNA at -70°C for long-term preservation [24]

- Avoid repeated freeze-thaw cycles by aliquoting RNA

- Use nuclease-free water or TE buffer for resuspension

- For short-term storage (days), -20°C is acceptable for high-quality RNA

Q5: What controls should I include when testing a new RNA isolation method? Always include:

- Positive control: Sample with known high-quality RNA

- Negative control: Extraction without input material

- Process control: RNA from the same source processed with your standard method

- Downstream validation: Test isolated RNA in your intended application (e.g., qPCR)

Essential Research Reagent Solutions

Table: Key Reagents for Optimal RNA Isolation and qPCR

| Reagent/Category | Function | Examples/Notes |

|---|---|---|

| RNA Stabilization Reagents [20] | Preserve RNA integrity during sample collection, storage, and transport | RNAlater, RNAstable, DNA/RNA Protection Reagent |

| Inhibitor-Resistant Master Mixes [7] | Enable reliable qPCR with partially purified RNA | GoTaq Endure, other specialized mixes with enhanced tolerance |

| DNase I Treatment Kits [24] [23] | Remove genomic DNA contamination | On-column and liquid-phase formats available |

| RNA Cleanup Kits [24] | Further purify RNA after initial extraction | Remove salts, inhibitors, and concentrate dilute samples |

| Quality Assessment Tools | Evaluate RNA quantity, purity, and integrity | Spectrophotometers, bioanalyzers, fluorometers |

| Specialized Lysis Buffers [19] | Optimized for specific sample types | Plant, bacterial, blood-specific formulations |

Selecting the appropriate RNA isolation method requires careful consideration of your sample type, downstream application, and throughput needs. By understanding the principles behind different extraction technologies and implementing the troubleshooting strategies outlined in this guide, researchers can significantly improve both RNA quality and subsequent qPCR performance. Remember that validation of any new method with your specific samples and applications remains essential for generating reliable, reproducible results in your research on qPCR efficiency with challenging RNA samples.

The accuracy and sensitivity of quantitative PCR (qPCR) are critically dependent on the quality of the input nucleic acids. When working with low-quality or complex RNA samples, common contaminants such as proteins, lipids, and salts can severely inhibit reverse transcription and PCR amplification, leading to unreliable data, poor amplification efficiency, and inconsistent results [2]. Advanced purification techniques are therefore essential for successful gene expression analysis, particularly in challenging sample types.

This technical support guide focuses on two powerful purification methods: phenol-chloroform extraction and lithium chloride (LiCl) precipitation. Phenol-chloroform extraction utilizes organic chemistry to efficiently separate nucleic acids from proteins and other cellular components [25], while LiCl precipitation offers a selective method for RNA isolation, effectively removing contaminating carbohydrates and small RNA species [2]. When implemented correctly, these techniques significantly improve RNA purity and subsequently enhance qPCR performance for low-quality starting materials, providing researchers with more reliable and reproducible data in drug development and diagnostic applications.

Technical FAQs: Addressing Common Experimental Challenges

Question: How do I know if my RNA sample requires phenol-chloroform purification before qPCR?

Answer: Indicators that your RNA sample may require more stringent purification include spectrophotometric readings outside the ideal ranges (A260/A280 < 1.8 or A260/A230 < 2.0) [2] [26], poor amplification efficiency in qPCR (standard curve slope < -3.6) [2], inconsistent replicate data [27], or amplification in no-template controls suggesting contamination [27] [28]. These signs often point to the presence of inhibitors such as proteins, polysaccharides, or residual salts that standard silica-column methods may not completely remove.

Question: What are the primary advantages and limitations of phenol-chloroform extraction compared to spin-column methods?

Answer: Phenol-chloroform extraction is highly effective at removing proteins and lipids from difficult samples and is relatively cost-effective for processing large volumes [25]. However, it is labor-intensive, requires careful handling of hazardous chemicals, and involves more steps than column-based methods [25]. In contrast, spin columns are faster and easier to use but may be less effective with heavily contaminated samples and have higher per-sample costs [29]. Magnetic bead-based systems like HighPrep PCR offer a modern alternative with high recovery rates (94-96%) and automation compatibility [29].

Question: When should I choose LiCl precipitation over other RNA purification methods?

Answer: LiCl precipitation is particularly advantageous when you need to selectively precipitate large RNAs while leaving behind contaminants like carbohydrates, small RNAs, and some salts [2]. This makes it ideal for samples rich in polysaccharides or when purifying specific RNA fractions. However, it is less effective for complete removal of proteins and may require combination with other purification methods for optimal results.

Question: My qPCR efficiency remains poor even after purification. What could be wrong?

Answer: Persistent poor efficiency after purification suggests residual inhibitors or RNA degradation. First, verify purification success by checking A260/A280 and A260/230 ratios [2] [26]. Ensure proper technique during phase separation to avoid protein carryover in phenol-chloroform extraction [25]. Consider diluting your template to reduce inhibitor concentration [2] [28], and always include appropriate controls (no-RT, NTC) to identify contamination sources [27] [28]. Also confirm that your primers do not bind to low-complexity regions or span SNP sites [2].

Troubleshooting Guide: Phenol-Chloroform & LiCl Precipitation

Table 1: Common Problems and Solutions for Phenol-Chloroform Extraction

| Problem | Possible Causes | Solutions |

|---|---|---|

| Low DNA yield | Incomplete phase separation; DNA retained in organic phase | Extend centrifugation time; ensure proper pH of phenol; avoid transferring intermediate layer [25] [30] |

| Protein contamination | Incomplete lysis; inadequate proteinase K digestion | Extend digestion time (up to 24h for rigid tissues); add fresh proteinase K [30]; optimize lysis buffer composition |

| RNA degradation | RNase contamination; excessive processing time | Use RNase-free reagents and equipment; work quickly on ice; include RNase inhibitors in lysis buffer |

| Poor qPCR efficiency after purification | Residual phenol or chloroform carryover | Repeat chloroform extraction step; ensure careful pipetting without disturbing organic phase [25] [30] |

| Aqueous phase turbidity | Incomplete tissue digestion | Add additional phenol-chloroform extraction cycle; extend proteinase K digestion time [30] |

Table 2: Common Problems and Solutions for LiCl Precipitation

| Problem | Possible Causes | Solutions |

|---|---|---|

| Low RNA recovery | Insufficient LiCl concentration; precipitation time too short | Use final LiCl concentration of 2-2.5M; extend precipitation time at -20°C overnight [2] |

| Salt contamination in precipitate | Inadequate washing | Increase number of 70% ethanol washes; ensure complete removal of supernatant between washes |

| DNA contamination in RNA prep | No DNase treatment | Include DNase I digestion step prior to precipitation [27] [28] |

| Poor RNA quality in downstream qPCR | Incomplete inhibitor removal | Combine with initial phenol-chloroform extraction for heavily contaminated samples [2] |

| Selective precipitation of large RNAs | Intrinsic property of LiCl | Use alternative methods if small RNA recovery is essential |

Experimental Protocols

Phenol-Chloroform Extraction Protocol

This protocol effectively removes proteins, lipids, and other contaminants from nucleic acid samples, making it ideal for challenging samples that compromise qPCR efficiency [25] [30].

Materials Required:

- Phenol:chloroform:isoamyl alcohol (25:24:1)

- Chloroform:isoamyl alcohol (24:1)

- Lysis buffer (e.g., TE buffer with SDS and proteinase K)

- Glycogen (20 μg/μL)

- 7.5M NH₄OAc (ammonium acetate) or 10M LiCl

- 100% and 70% ethanol

- TE buffer (10mM Tris-HCl, 1mM EDTA, pH 8.0) or nuclease-free water

Procedure:

- Sample Preparation: Homogenize biological sample completely. For tissues, grind in liquid nitrogen then resuspend in lysis buffer. For cells, resuspend directly in lysis buffer [25] [30].

- Cell Lysis: Incubate at 55°C for 1-2 hours or until completely lysed. For difficult tissues, extend digestion time up to 24 hours with additional proteinase K if needed [30].

- RNase Treatment (for DNA extraction): Add 10μL RNase A (10mg/mL), incubate 3 minutes at room temperature [30].

- Phenol-Chloroform Extraction: Add equal volume phenol:chloroform:isoamyl alcohol (25:24:1). Vortex vigorously for 30 seconds. Centrifuge at 14,000 rpm for 3-5 minutes at room temperature [25] [30].

- Phase Separation: Carefully transfer upper aqueous phase to new tube without disturbing interphase. For dirty samples, repeat steps 4-5 [30].

- Chloroform Extraction: Add equal volume chloroform:isoamyl alcohol (24:1). Vortex and centrifuge as in step 4. Transfer aqueous phase to new tube [25] [30].

- Nucleic Acid Precipitation: Add 1/10 volume 7.5M NH₄OAc (for DNA) or 1/4 volume 10M LiCl (for RNA), followed by 2.5 volumes 100% ethanol. Mix well by inversion [25] [30].

- Precipitation: Incubate at -20°C overnight or at -80°C for at least 1 hour.

- Pellet Formation: Centrifuge at 14,000 rpm for 20-30 minutes at 4°C. Carefully discard supernatant [25] [30].

- Wash: Add 1mL 70% ethanol, invert tube several times. Centrifuge at 14,000 rpm for 5 minutes at 4°C. Discard supernatant. Repeat wash step [30].

- Drying: Air dry pellet for 5-10 minutes until moist but not completely dry [30].

- Resuspension: Resuspend DNA/RNA pellet in 50-100μL TE buffer or nuclease-free water. Incubate at 55°C for 1-2 hours with occasional mixing to dissolve [25] [30].

LiCl Precipitation Protocol for RNA

This method selectively precipitates high molecular weight RNA while leaving behind contaminants, ideal for improving qPCR results from low-quality RNA samples [2].

Materials Required:

- 10M LiCl solution (RNase-free)

- 100% and 70% ethanol (RNase-free)

- Nuclease-free water or TE buffer

- Glycogen (optional, for low concentration samples)

Procedure:

- Sample Preparation: Start with RNA in aqueous solution (e.g., after phenol-chloroform extraction or column elution).

- Add LiCl: Add 1/4 volume of 10M LiCl to obtain a final concentration of 2M. Mix thoroughly by inversion.

- Precipitate: Incubate at -20°C for at least 4 hours or overnight for maximum recovery.

- Pellet RNA: Centrifuge at 14,000 rpm for 30 minutes at 4°C to pellet RNA.

- Wash: Carefully discard supernatant. Wash pellet with 1mL 70% ethanol. Centrifuge at 14,000 rpm for 5 minutes at 4°C.

- Repeat Wash: Discard supernatant and repeat wash step to ensure complete salt removal.

- Dry: Air dry pellet for 5-10 minutes until no ethanol remains but pellet is still slightly moist.

- Resuspend: Resuspend RNA in nuclease-free water or TE buffer. Incubate at 55°C for 10-15 minutes with occasional gentle mixing to dissolve completely.

- Quality Control: Measure RNA concentration and purity using spectrophotometry (A260/A280 ~2.0) [2].

Workflow Visualization

Nucleic Acid Purification Workflow: This diagram illustrates the integrated purification process showing where phenol-chloroform extraction and selective precipitation methods fit within the complete workflow for preparing high-quality nucleic acids for qPCR applications.

Research Reagent Solutions

Table 3: Essential Reagents for Advanced Nucleic Acid Purification

| Reagent/Kit | Function | Application Notes |

|---|---|---|

| Phenol:Chloroform:Isoamyl Alcohol (25:24:1) | Denatures and extracts proteins; separates nucleic acids into aqueous phase | Critical ratio maintains phase separation; phenol denatures proteins, chloroform removes lipids [25] [30] |

| Lithium Chloride (LiCl) | Selective precipitation of high molecular weight RNA | Effective for removing carbohydrates and small RNAs; use at 2M final concentration [2] |

| Proteinase K | Digests protein contaminants and nucleases | Essential for complete cell lysis; requires extended incubation for tough tissues [30] |

| Glycogen | Carrier for nucleic acid precipitation | Improves recovery of low concentration samples (20μg/mL working concentration) [25] |

| Ammonium Acetate (NH₄OAc) | Salt for ethanol precipitation of DNA | Preferred over sodium acetate for DNA as it better precipitates DNA without co-precipitating dNTPs [25] |

| Monarch Spin PCR & DNA Cleanup Kit | Alternative column-based purification | High recovery for fragments 50bp-25kb; low elution volumes (5μL) for concentrated DNA [26] |

| HighPrep PCR Magnetic Beads | Magnetic bead-based cleanup | 94-96% recovery; suitable for automation; enables size selection via bead ratio adjustment [29] |

| Antarctic Thermolabile UDG | Prevents carryover contamination in qPCR | Eliminates PCR products from previous reactions; use at 0.2U/μL concentration [27] |

Primer and Probe Design for Specificity and Robustness

Core Principles of Primer and Probe Design

What are the fundamental rules for designing specific and robust qPCR primers?

Effective primer design is the foundation of a successful qPCR assay. Adherence to the following rules ensures high specificity and robust amplification [31].

- Length: Primers should be 18–30 nucleotides long. This range is sufficient for specificity while allowing for a manageable melting temperature (Tm) [31].

- Melting Temperature (Tm): The optimal Tm for primers is 60–64°C, with an ideal target of 62°C. The Tm values for the forward and reverse primer pair should not differ by more than 2°C to ensure both bind to the target simultaneously with similar efficiency [31].

- GC Content: The GC content should be between 35–65%, with an ideal of 50%. Avoid regions of 4 or more consecutive G residues, as this can promote non-specific binding [31] [32].

- Annealing Temperature (Ta): The annealing temperature should be set no more than 5°C below the Tm of your primers. A Ta that is too low leads to non-specific amplification, while a Ta that is too high reduces reaction efficiency [31].

- Specificity and Secondary Structures: Primers must be specific to the target sequence. Use tools like NCBI BLAST to ensure uniqueness. Screen designs for self-dimers, heterodimers, and hairpin structures; the ΔG for any such structures should be weaker (more positive) than -9.0 kcal/mol [31].

How should hydrolysis probes (like TaqMan) be designed for optimal performance?

For probe-based assays, follow these guidelines in addition to the general rules above [31]:

- Location: The probe should be placed in close proximity to a primer-binding site but must not overlap with it.

- Melting Temperature (Tm): The probe should have a Tm that is 5–10°C higher than the primers. This ensures the probe is fully bound before primer extension begins.

- Length: For single-quenched probes, a length of 20–30 bases is recommended. For double-quenched probes (which are recommended for lower background and higher signal), longer lengths can be used.

- Sequence: Avoid having a G at the 5' end, as it can quench the fluorophore's fluorescence.

How can I design primers to avoid genomic DNA amplification?

To ensure your qPCR assay is specific to cDNA and does not amplify contaminating genomic DNA (gDNA), follow these practices [31] [32]:

- Span Exon-Exon Junctions: Design primers so that the amplicon spans an exon-exon junction. The primer binding sites should be on different exons, making amplification from gDNA (which contains introns) inefficient or impossible due to the large intervening sequence.

- DNase Treatment: As a general lab practice, treat your RNA samples with DNase I during purification to degrade any residual gDNA.

Troubleshooting Guides

Table 1: Troubleshooting Poor Amplification or No Product

| Observation | Possible Cause | Recommended Solution |

|---|---|---|

| No Product | Suboptimal primer design | Redesign primers, ensure specificity with BLAST, and check for secondary structures [33] [34]. |

| Annealing temperature too high | Lower the annealing temperature in 2°C increments or perform a temperature gradient PCR [34] [35]. | |

| Too little template or primer | Increase template amount; optimize primer concentration (typically 0.1–1 μM) [33] [34]. | |

| PCR inhibitors in sample | Further purify the template DNA/RNA via ethanol precipitation or column purification [2] [33]. | |

| Complex template (e.g., high GC%) | Use a polymerase or master mix specifically formulated for difficult templates and/or use PCR additives [33] [35]. | |

| Low Efficiency (Slope < -3.6) | Poor primer/probe design | Redesign primers/probe to meet optimal criteria for Tm, GC%, and specificity [2]. |

| PCR inhibitors | Check sample purity (A260/A280 ratio); re-purify if necessary [2]. | |

| Inaccurate pipetting | Calibrate pipettes, especially for low volumes (<5 μL); ensure thorough mixing [2]. | |

| Suboptimal reaction conditions | Optimize Mg2+ concentration and annealing temperature [33] [34]. |

Table 2: Troubleshooting Non-Specific Amplification or Multiple Bands

| Observation | Possible Cause | Recommended Solution |

|---|---|---|

| Multiple Bands or Primer-Dimers | Annealing temperature too low | Increase the annealing temperature in 2°C increments [33] [34]. |

| Primer concentration too high | Lower the primer concentration within the 0.1–1 μM range [33] [34]. | |

| Excessively long annealing time | Shorten the annealing time to minimize non-specific binding [33]. | |

| Non-specific primer binding | Use a hot-start polymerase; redesign primers to avoid complementary regions [33] [34]. | |

| Too much template | Reduce the amount of input template by 2–5 fold [35]. |

Troubleshooting Logic for Common qPCR Issues

Step-by-Step Experimental Protocols

Protocol 1: Stepwise Optimization of a New qPCR Assay

This protocol ensures your primers achieve maximum efficiency and specificity before use in experimental samples [17].

In Silico Design and Specificity Check:

- Use design tools (e.g., Primer-BLAST, OligoAnalyzer) to create candidate primers adhering to the core principles.

- Perform a BLAST search to verify primer specificity to your intended target.

- Check for and avoid secondary structures (hairpins, self-dimers) and complementarity between forward and reverse primers.

Empirical Annealing Temperature Optimization:

- Set up a qPCR reaction with your primer pair and a positive control template (e.g., a plasmid containing the target sequence or a high-quality cDNA pool).

- Run a thermal gradient PCR (e.g., from 55°C to 68°C) to determine the optimal annealing temperature (Ta).

- The optimal Ta is one that yields the lowest Cq value and the highest fluorescence amplitude, indicating specific and efficient amplification.

Primer Concentration Optimization:

- Using the optimal Ta from step 2, test different primer concentrations (e.g., 50 nM, 100 nM, 200 nM, 500 nM) in a checkerboard fashion (varying forward and reverse independently).

- Select the concentration combination that gives the lowest Cq and highest fluorescence without generating primer-dimers in the no-template control (NTC).

Generation of a Standard Curve and Efficiency Calculation:

- Prepare a 5-point, 1:5 or 1:10 serial dilution of your cDNA pool.

- Run qPCR on the dilution series with the optimized conditions.

- Analyze the standard curve. A robust assay should have an R² ≥ 0.99 and an amplification efficiency between 90% and 105% (corresponding to a slope of -3.6 to -3.3) [2] [17].

Protocol 2: A Method for qPCR Analysis That Corrects for Amplification Efficiency

This data analysis method enhances accuracy by accounting for imperfect amplification efficiency, which is common in practice [36].

Prepare a Standard Series:

- Create a mix of cDNA from all experimental samples. Designate this as "Standard 1" with a concentration of 1 Arbitrary Unit (AU).

- Perform a 2-fold serial dilution of Standard 1 in nuclease-free water to create at least 5 additional standards (e.g., 1, 0.5, 0.25, 0.125, 0.0625 AU).

Run qPCR:

- Include the standard series, your experimental samples, and no-template controls (NTCs) on the same qPCR plate for each gene of interest and housekeeping gene.

- Use technical triplicates to ensure precision.

Calculate the Experimental Amplification Factor:

- For each gene, plot the mean Cq values of the standard series against the log2-transformed concentrations.

- Perform a linear regression. A good curve will have an R² > 0.99.

- Calculate the slope of the regression line.

- Calculate the experimental amplification factor (E) using the formula: E = 2^(-1/slope).

- An efficiency of 100% (slope = -3.32) gives E=2. Use this E value in subsequent relative quantification calculations instead of assuming a perfect efficiency of 2 [36].

Primer Design and Validation Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Tools and Reagents for qPCR Assay Development

| Item | Function/Benefit | Example Tools/Suppliers |

|---|---|---|

| Primer Design Software | Calculates Tm, GC%, checks for secondary structures, and validates specificity. | Primer-BLAST [17], IDT OligoAnalyzer [31], Primer3Plus [32] [17] |

| Hot-Start DNA Polymerase | Reduces non-specific amplification and primer-dimer formation by requiring heat activation. | Various commercial master mixes (e.g., from Thermo Fisher, Takara Bio, NEB) [33] [34] |

| PCR Additives | Helps denature complex templates (e.g., GC-rich sequences) and improves amplification efficiency. | DMSO, GC Enhancer solutions [33] |

| Nucleic Acid Purification Kits | Removes PCR inhibitors (proteins, salts, organics) from samples, crucial for robust amplification. | RNeasy kits (QIAGEN), NucleoSpin kits (Takara Bio), Monarch kits (NEB) [2] [36] |

| Standard Curve Material | Allows for calculation of amplification efficiency and accurate relative quantification. | Serial dilutions of a pooled cDNA sample [36] or synthetic gBlocks [2] |

Frequently Asked Questions (FAQs)

My qPCR results show high variability between replicates. What could be the cause?

High technical variability is often a result of pipetting errors, especially with very small volumes (< 5 μL). Ensure your pipettes are regularly calibrated. Other causes include low template concentration (entering the stochastic zone where copy number is very low) or inconsistent reaction mixing. Always prepare a master mix to minimize tube-to-tube variation and briefly centrifuge the plate before running [2].

How can I prevent contamination in my qPCR experiments?

Contamination, often from previous PCR products (amplicons), is a major source of false positives. Establish physically separated pre- and post-PCR work areas with dedicated equipment (pipettes, tips, lab coats). Use UDG (uracil-DNA glycosylase) treatment or purchase master mixes that include it to enzymatically destroy carryover contamination from prior reactions. Always include no-template controls (NTCs) to monitor for contamination [35].

My primer BLAST looks perfect, but the assay still doesn't work. What should I do next?

In silico analysis is a first step, but it does not guarantee experimental success. The sequence used for design might be incorrect or not match your sample. Furthermore, BLAST may miss regions of stable, non-exact matching that still allow primer binding. You must empirically optimize the assay as outlined in Protocol 1, focusing on annealing temperature and primer concentration. Finally, verify the quality and integrity of your template RNA/DNA, as degradation is a common culprit [37] [17].

Leveraging Inhibitor-Tolerant Master Mixes and Direct Amplification Workflows

Frequently Asked Questions (FAQs)

What are the main advantages of using a direct PCR workflow?

Direct PCR provides several key benefits for laboratory efficiency:

- Time and Cost Savings: It eliminates the DNA extraction and purification steps, reducing a multi-hour process to minutes and saving on extraction kit costs [38].

- Minimized DNA Loss: Conventional DNA extraction can lead to the loss of over 80% of your starting DNA material. Direct PCR avoids this, making it particularly valuable for samples with low initial DNA content [38].

- Reduced Contamination Risk: With fewer handling and processing steps, the opportunities for sample contamination are significantly lowered [38].

My qPCR results show poor efficiency. How can I tell if inhibitors are the cause?

Inhibition in qPCR can be identified through several tell-tale signs in your amplification data [7] [5] [2]:

- Delayed Quantification Cycle (Cq): All samples, including positive controls, show consistently higher Cq values than expected.

- Abnormal Standard Curve: The slope of your standard curve falls outside the ideal range of -3.6 to -3.3, corresponding to a PCR efficiency below 90% or above 110% [5] [2].

- Altered Dilution Factor ΔCq: In a 10-fold dilution series, the difference in Cq (ΔCq) between dilutions is less than the theoretical value of 3.3. For instance, a ΔCq of only 2.8 between consecutive dilutions indicates the presence of inhibitors in the more concentrated sample [5] [2].

- Abnormal Amplification Curves: The curves may appear flattened, show inconsistent exponential growth, or fail to cross the detection threshold altogether [7].

Are some PCR techniques more resistant to inhibitors than others?

Yes, digital PCR is generally more tolerant of PCR inhibitors than quantitative PCR [6] [8]. There are two primary reasons for this:

- Endpoint Detection: dPCR does not rely on amplification kinetics for quantification. It simply counts the number of positive reactions at the end of the PCR, making it less sensitive to factors that slow down the reaction [6].

- Sample Partitioning: The partitioning of a single sample into thousands of individual reactions effectively dilutes the inhibitors, reducing their concentration in any given reaction chamber and minimizing their interference [6] [8].

Besides using a specialized master mix, what can I add to my reaction to overcome inhibition?

Several chemical enhancers can be spiked into your PCR to mitigate the effects of common inhibitors [8]:

- Proteins: Bovine Serum Albumin (BSA) and T4 gene 32 protein (gp32) can bind to inhibitory compounds like humic acids, preventing them from interfering with the DNA polymerase [8].

- Detergents: TWEEN-20 can counteract inhibitory effects on the Taq DNA polymerase [8].

- Organic Solvents: Dimethyl Sulfoxide (DMSO) and formamide can enhance amplification by lowering the melting temperature of DNA or destabilizing secondary structures [8].

- Other Additives: Glycerol can help by protecting enzymes from denaturation [8].

Troubleshooting Guide: Common Problems and Solutions

| Problem | Possible Cause | Recommended Solution |

|---|---|---|

| High Cq/Delayed Amplification | Presence of PCR inhibitors from sample (e.g., hemoglobin, heparin, humic acids) or extraction (e.g., ethanol, phenol) [7] [2]. | Use an inhibitor-tolerant master mix. Dilute the template DNA. Add PCR enhancers like BSA [7] [8]. |

| Poor Amplification Efficiency (<90%) | Inhibitors affecting polymerase activity or primer binding; suboptimal primer/probe design [7] [2]. | Redesign primers/probe. Further purify the nucleic acid template. Use a master mix with inhibitor-resistant enzymes [7] [2]. |

| Inconsistent Replicates | Inaccurate pipetting, especially of low volumes. Inhomogeneous sample due to inhibitors [2]. | Calibrate pipettes and use proper technique. Briefly spin down plates. Ensure sample is thoroughly mixed [2]. |

| Complete Amplification Failure | High concentration of potent inhibitors (e.g., in complex samples like wastewater, soil, or blood) [6] [8]. | Employ a multi-pronged approach: use a specialized direct PCR master mix, dilute the sample, and include enhancers like gp32 or TWEEN-20 [8]. |

Research Reagent Solutions

The following table details key reagents that are essential for implementing robust inhibitor-tolerant and direct amplification protocols.

| Reagent | Function in Inhibitor-Tolerant Workflows |

|---|---|

| Inhibitor-Tolerant DNA Polymerase | Engineered enzyme (e.g., Phusion Flash, KOD FX) that maintains activity in the presence of common inhibitors like humic substances, hemoglobin, and polysaccharides [6] [38]. |

| Specialized qPCR Master Mix | Pre-mixed solutions (e.g., GoTaq Endure, PrimeTime) containing inhibitor-resistant polymerase, buffer, and enhancers designed for reliable amplification from challenging samples like blood, soil, and plant material [7] [39]. |

| Direct PCR Master Mix | Formulations that allow amplification directly from crude samples (e.g., buccal swabs, blood spots, bacterial colonies) without prior DNA extraction, often including lysis buffers and robust enzymes [38] [40]. |

| PCR Enhancers (BSA, gp32) | Additives that bind to inhibitory compounds, neutralizing their effect and freeing the polymerase to function normally [8]. |

| Lysis Buffer | A solution used in direct PCR to break open cells and release DNA, often with a short heating step, preparing the sample for immediate amplification [38]. |

Workflow and Protocol Diagrams

Standard versus Direct PCR Workflow

The following diagram illustrates the key procedural differences between a standard PCR workflow and a direct PCR workflow.

Decision Guide for Inhibitor Troubleshooting

Use this logical flowchart to diagnose and address suspected PCR inhibition in your experiments.

Template Dilution as a Simple Strategy to Overcome Inhibition

In quantitative PCR (qPCR) and reverse transcription qPCR (RT-qPCR), the presence of inhibitors in the reaction is a frequent challenge that can severely compromise the accuracy and reliability of your results. Inhibition leads to skewed data, reduced sensitivity, and can even generate efficiencies that appear to exceed the theoretical maximum of 100% [5]. This article outlines how template dilution serves as a straightforward and effective experimental strategy to overcome this inhibition, ensuring data integrity.

Frequently Asked Questions (FAQs)

1. How can I tell if my qPCR reaction is inhibited?

Inhibition is often indicated by a flattening of the standard curve's slope when using a serial dilution of your template. A significant sign is a smaller than expected difference in quantification cycle (Cq) values between dilutions. For a 10-fold dilution with 100% efficiency, the ΔCq should be approximately 3.3. A consistently lower ΔCq suggests inhibition [5]. Furthermore, an amplification efficiency calculated to be significantly over 110% can also be a direct indicator of inhibition in your samples [5].

2. Why does diluting the template help overcome inhibition?

Inhibitors are diluted along with the template. In a concentrated sample, the inhibitor-to-template ratio may be high enough to significantly hamper the polymerase enzyme. As you dilute the sample, this ratio decreases, and the concentration of the inhibitor can fall below a critical threshold where its effect becomes negligible, allowing the amplification to proceed at its proper efficiency [5].

3. What are common sources of PCR inhibitors?

Inhibitors can be introduced at various stages. Common culprits include:

- Carryover from sample preparation: Phenol, ethanol, sodium dodecyl sulfate (SDS), and salts [5] [33].

- Biological samples: Hemoglobin, heparin, polysaccharides, and chlorophylls [5].

- Complex templates: Excessive amounts of genomic DNA or secondary structures in the template itself [33].

4. My dilution worked, but now my target is too dilute to detect. What are my options?

If dilution pushes your target concentration below the detection limit, consider the following:

- Purify the sample: Use alcohol precipitation, drop dialysis, or a commercial PCR cleanup kit to physically remove the inhibitors instead of, or prior to, diluting [33] [41].

- Use a more robust enzyme: Select a DNA polymerase known for high processivity and tolerance to common inhibitors [33].

- Increase sample volume: If possible, increase the amount of template in the reaction to compensate for dilution, provided this does not reintroduce a problematic amount of inhibitor.

Troubleshooting Guide: Using Template Dilution

| Observation | Possible Cause | Recommended Solution |

|---|---|---|

| Abnormally high amplification efficiency (>110%) | Presence of polymerase inhibitors in the concentrated sample [5]. | 1. Perform a dilution series: Test a 1:10 and 1:100 dilution of your template.2. Re-calculate efficiency: Use the Cq values from the dilutions where the ΔCq approaches 3.3. Exclude the concentrated sample from the final efficiency calculation [5]. |

| Reduced amplification efficiency (<90%) | Non-optimal reagent concentrations, bad primer design, or poor reaction conditions [5]. | Troubleshoot primer design, optimize Mg2+ concentration, and ensure reagent freshness. Template dilution is less likely to resolve this specific issue [33] [41]. |

| Inconsistent Cq values across a dilution series | Inhibitors are present but are being diluted out, or stochastic effects in very dilute samples [5]. | 1. Omit problematic points: Exclude both the most concentrated (inhibited) and the most diluted (high variability) samples from your standard curve.2. Use intermediate dilutions: Focus on the dilutions that produce a linear and consistent ΔCq [5]. |

Experimental Protocol: Dilution Series to Test for and Overcome Inhibition

This protocol provides a step-by-step method to identify inhibition and determine a suitable working dilution for your samples.

Materials Required

- Nuclease-free water

- Sterile, DNA-free microcentrifuge tubes

- Accurate pipettes and tips

- Your purified nucleic acid template (DNA or RNA)

- qPCR or RT-qPCR master mix, primers, and probes

Procedure

- Prepare Stock Dilution: Create an initial 1:10 dilution of your purified nucleic acid sample using nuclease-free water.

- Perform Serial Dilutions: From the 1:10 dilution, perform a serial dilution to prepare 1:100 and 1:1000 templates.

- Run qPCR: Amplify each dilution (including the original, undiluted sample) in duplicate or triplicate using your standard qPCR cycling conditions.

- Analyze Results:

- Plot the log of the dilution factor against the obtained Cq values for each sample.