Mastering Primer-Dimer Prevention: A Researcher's Guide to Optimizing SYBR Green qPCR Assays

This comprehensive guide addresses the critical challenge of primer-dimer formation in SYBR Green qPCR assays, providing researchers and drug development professionals with both foundational knowledge and practical solutions.

Mastering Primer-Dimer Prevention: A Researcher's Guide to Optimizing SYBR Green qPCR Assays

Abstract

This comprehensive guide addresses the critical challenge of primer-dimer formation in SYBR Green qPCR assays, providing researchers and drug development professionals with both foundational knowledge and practical solutions. Covering the fundamental mechanisms behind non-specific amplification, the article details advanced methodological approaches for assay design, systematic troubleshooting protocols for optimization, and validation strategies comparing SYBR Green to probe-based alternatives. Through evidence-based techniques including rigorous primer design, melting curve analysis, and reaction optimization, this resource enables scientists to significantly improve data accuracy and reliability in gene expression analysis, pathogen detection, and diagnostic assay development while maintaining cost-effectiveness.

Understanding Primer-Dimer Formation: The Science Behind SYBR Green Artifacts

FAQ 1: What is the fundamental binding mechanism of SYBR Green I to dsDNA?

SYBR Green I (SG) is an asymmetrical cyanine dye that binds to double-stranded DNA (dsDNA) through two primary modes, which are dependent on the ratio of dye molecules to DNA base pairs (dbpr) [1].

- Intercalation: At low dbprs (below approximately 0.15), SYBR Green I molecules primarily intercalate between the base pairs of the DNA double helix [1].

- Surface Binding: At higher dbprs (above approximately 0.15), the dye undergoes surface binding to the DNA molecule. It is this surface binding mode that leads to a significant increase in fluorescence intensity, which is the basis for its use in detection [1].

The fluorescence enhancement occurs because the dye's structure is held more rigidly when bound to DNA. In solution, the unbound dye can rotate freely, and its energy is dissipated through non-radiative processes. When bound, this mobility is restricted, forcing the molecule to release energy through fluorescence [2]. The binding is sequence-independent but can be influenced by salt concentrations and DNA sequence, with studies showing different binding affinities for homopolymers like poly(dA)·poly(dT) and poly(dG)·poly(dC) [1].

FAQ 2: What quantitative data characterizes SYBR Green I binding?

The performance and binding of SYBR Green I can be characterized by several key photophysical and biochemical parameters. The table below summarizes core quantitative data essential for experimental design and troubleshooting.

Table 1: Key Quantitative Data for SYBR Green I

| Parameter | Typical Value or Characteristic | Experimental Implication |

|---|---|---|

| Excitation Maximum | 494 nm [3], 497 nm [4] | Optimal for standard blue-light sources (e.g., 488 nm laser). |

| Emission Maximum | 521 nm [3], 520 nm [4] | Detected in the green channel of instruments. |

| Fluorescence Increase | Up to 1000-fold upon binding dsDNA [5] | Provides high sensitivity for detecting small amounts of DNA. |

| Critical Binding Mode Transition | ~0.15 dye molecules per base pair (dbpr) [1] | Dye concentration in the reaction must be sufficient for surface binding. |

| Binding to ssDNA/RNA | Binds with lower affinity; fluorescence at least 11-fold lower than dsDNA [1] | Can cause background signal; RNase treatment may be necessary for cellular assays [5]. |

| Mutagenicity (Ames Test) | Approximately 30x less mutagenic than ethidium bromide [4] | Considered safer, but standard handling precautions for DNA intercalators are advised. |

FAQ 3: What advanced protocols validate SYBR Green I binding and specificity?

Beyond simple binding, specific protocols are used to leverage SYBR Green I for quantitative analysis. A key method is Melting Curve Analysis, which is critical for verifying assay specificity and troubleshooting issues like primer-dimer formation [6].

Table 2: Key Reagents for SYBR Green I qPCR

| Reagent Category | Example | Function |

|---|---|---|

| Fluorescent Dye | SYBR Green I | Binds dsDNA and fluoresces, enabling real-time detection [5]. |

| Hot-Start DNA Polymerase | Antibody-inactivated Taq | Prevents non-specific amplification and primer-dimer formation prior to the first high-temperature step [3]. |

| Passive Reference Dye | ROX | Normalizes for well-to-well variations in reaction volume or pipetting inaccuracies on some instruments [7]. |

| Reaction Buffer | Optimized ReadyMix | Provides optimal salt (Mg²⁺) and pH conditions for efficient amplification [7]. |

The following workflow outlines the standard procedure for a SYBR Green I qPCR assay followed by melt curve analysis:

Protocol Steps:

- Assay Setup: A typical multiplex SYBR Green reaction is set up to target specific genes along with an internal control. For example, one protocol for SARS-CoV-2 detection was optimized to simultaneously target the virus's N and E genes and the human β-actin gene as an internal control in a single tube [8].

- Thermal Cycling and Fluorescence Acquisition: The reaction is run in a real-time PCR instrument. Fluorescence is measured at the end of each extension cycle, generating an amplification plot [7].

- Melting Curve Analysis: After cycling, the protocol executes the melt curve stage. The temperature is gradually increased from a low temperature (e.g., 60°C) to a high temperature (e.g., 95°C), while continuously monitoring fluorescence. As the DNA denatures (melts), the SYBR Green I is released, and the fluorescence decreases [6] [8].

- Data Interpretation: The raw fluorescence data is converted into a melt curve by plotting the negative derivative of fluorescence with respect to temperature (-dF/dT) against the temperature. A single, sharp peak typically indicates specific amplification of a single product. Multiple peaks, broad peaks, or peaks at lower temperatures suggest non-specific amplification or primer-dimer formation [6].

FAQ 4: How can I troubleshoot primer-dimer formation in SYBR Green assays?

Primer-dimer (PD) is a common artifact where primers anneal to each other rather than the template, creating short, double-stranded DNA products that SYBR Green I will bind to, generating a false fluorescent signal [6]. The melt curve is your primary tool for identifying PD, as it typically melts at a lower temperature than your specific amplicon [6].

Table 3: Troubleshooting Primer-Dimer Formation

| Problem | Possible Cause | Solution |

|---|---|---|

| Low Tm peak in melt curve | Excess primers; low annealing temperature; poorly designed primers [6]. | - Optimize primer concentrations [7].- Increase annealing temperature [6].- Redesign primers with software to avoid self-complementarity [9]. |

| Non-specific amplification | Primers binding to non-target sites; suboptimal Mg²⁺ concentration [6]. | - Use a Hot-Start polymerase [3].- Optimize Mg²⁺ concentration [7].- Perform a temperature gradient to find optimal annealing [9]. |

| General Assay Optimization | Lack of robustness leading to variable performance. | - Test primers over a temperature gradient; an assay that works over a broad range (e.g., 3-5°C) is more robust [9].- Use systems like the Homo-Tag Assisted Non-Dimer (HAND) to reduce primer-dimer formation [10]. |

FAQ: Understanding Primer-Dimers

What is a primer-dimer? A primer-dimer (PD) is a small, unintended by-product in polymerase chain reaction (PCR) that forms when two primers anneal to each other via complementary base sequences instead of binding to the intended target DNA. This creates a short, double-stranded DNA fragment that the DNA polymerase can amplify, competing for reagents and potentially inhibiting the desired amplification [11] [12].

How do primer-dimers form? The formation occurs in several key steps. First, two primers anneal at their 3' ends due to complementary bases (Step I). If this hybridized structure is stable, DNA polymerase binds and extends both primers, creating a short double-stranded product (Step II). In subsequent PCR cycles, this new double-stranded molecule can serve as a template, leading to exponential amplification of the primer-dimer product itself [11]. An alternative mechanism suggests that background genomic DNA can sometimes serve as a scaffold, bringing two primers into close proximity even with minimal 3'-end complementarity, facilitating dimer formation [13].

Why are primer-dimers a particular concern in SYBR Green assays? SYBR Green dye binds non-specifically to all double-stranded DNA (dsDNA). When primer-dimers form, the dye binds to them and fluoresces, generating a false-positive signal that can interfere with the accurate quantification of your intended target [6] [14]. In probe-based assays, while the signal mechanism is more specific, primer-dimers still deplete essential reaction reagents (dNTPs, primers, polymerase), reducing amplification efficiency [14].

What do primer-dimers look like on a gel? After gel electrophoresis, primer-dimers typically appear as a fuzzy smear or a band of high intensity in the 30-50 base pair (bp) range, which is distinguishable from the longer, well-defined band of a specific target amplicon [11] [12].

Troubleshooting Guide: Preventing and Identifying Primer-Dimers

Prevention Strategies

| Strategy | Description | Key Details |

|---|---|---|

| Optimized Primer Design | Design primers with software to minimize complementarity. | Use software (e.g., Primer3, Primer-BLAST) to avoid self-complementarity and 3'-end complementarity between primers. Ideal primers are 18-30 bp with 40-60% GC content [11] [15]. |

| Hot-Start PCR | Use a modified DNA polymerase inactive at room temperature. | Prevents enzymatic activity during reaction setup. The polymerase is activated only after a high-temperature initial denaturation step [11]. |

| Thermal & Chemical Optimization | Adjust reaction conditions to favor specific priming. | Increase annealing temperature to reduce non-specific binding; Lower primer concentration to decrease primer-primer interactions [11] [12]. |

| Structural Modifications | Use chemically modified primers that resist dimerization. | Examples include chimeric RNA-DNA primers or primers with special nucleotide analogues (SAMRS) that bind to natural DNA but not to each other [11]. |

Detection and Identification Methods

| Method | Application | How to Interpret Results |

|---|---|---|

| Melting Curve Analysis | Essential QC for SYBR Green qPCR. | After amplification, slowly increase temperature while monitoring fluorescence. A single, sharp peak indicates a specific product. Multiple peaks, shoulders, or a low-temperature peak suggest primer-dimer formation [11] [6]. |

| Gel Electrophoresis | Standard method for conventional PCR. | Primer-dimers appear as a fast-migrating, smeary band around 30-100 bp. Running a No-Template Control (NTC) is crucial: a band in the NTC confirms primer-dimer formation [11] [12] [14]. |

| No-Template Control (NTC) | Critical control for all PCR types. | A reaction tube containing all reagents except the DNA template. Any amplification signal (in qPCR) or band (on a gel) is due to primer-dimer or contamination [12]. |

Experimental Data and Protocols

Quantitative Insights from Experimental Studies

Advanced capillary electrophoresis studies have provided quantitative insights into the biophysical parameters of primer-dimer formation. The following table summarizes key experimental findings on heterodimerization between two 30-mer primers [16].

| Experimental Parameter | Finding | Implication for Assay Design |

|---|---|---|

| Stability vs. Temperature | Dimerization was inversely correlated with temperature for partially complementary primers. | Higher annealing/extension temperatures can suppress dimerization of imperfectly matched primers. |

| Minimum Consecutive Basepairs | Stable dimerization required more than 15 consecutive basepairs to form. | Software checks should flag primer pairs with long contiguous complementary regions. |

| Role of Non-consecutive Basepairs | 20 out of 30 non-consecutive basepairs did not create stable dimers. | Total complementarity is less critical than long, uninterrupted stretches of complementary sequence. |

Core Experimental Protocol: Checking for Primer-Dimers with Melt Curve Analysis

This protocol is a standard quality control step for SYBR Green qPCR assays [6].

- Prepare the Reaction: Set up your qPCR reaction as usual, using SYBR Green as the fluorescent reporter. Always include a No-Template Control (NTC).

- Run the qPCR Program: Use your standard cycling conditions (e.g., 40 cycles of denaturation, annealing, and extension).

- Perform the Melt Curve Stage: Immediately after the final PCR cycle, add the following step to your instrument run:

- Denature: 95°C for 15 seconds.

- Annealing/Hold: 60°C for 20 seconds.

- Melt/Ramp: Gradually increase the temperature from 60°C to 95°C (e.g., at a rate of 0.3°C per second) while continuously monitoring the fluorescence.

- Analyze the Data: Plot the data as the negative derivative of fluorescence over temperature (-dF/dT) vs. Temperature. A single, sharp peak indicates a single, specific amplicon. Multiple peaks or a peak at a lower temperature indicates non-specific amplification or primer-dimers.

Research Reagent Solutions

| Reagent / Material | Function in Preventing/Detecting Primer-Dimers |

|---|---|

| Hot-Start DNA Polymerase | Critical for preventing pre-PCR activity; reduces non-specific amplification and primer-dimer formation during reaction setup [11] [12]. |

| SYBR Green I Dye | A nonspecific intercalating dye used for qPCR; requires melt curve analysis to distinguish specific product from primer-dimer signal [11] [6]. |

| Sequence-Specific Probes (TaqMan) | Provides target-specific signal; does not generate fluorescence from primer-dimers, thereby improving quantification accuracy [11] [14]. |

| BOXTO Dye | An alternative dsDNA dye that can be multiplexed with probes; allows real-time monitoring of total dsDNA (including primer-dimers) in probe-based assays without post-run gel electrophoresis [14]. |

| Primer Design Software | Algorithms (e.g., Primer3, Oligo) check for self-complementarity, hairpins, and inter-primer complementarity to design optimal primers [11] [15]. |

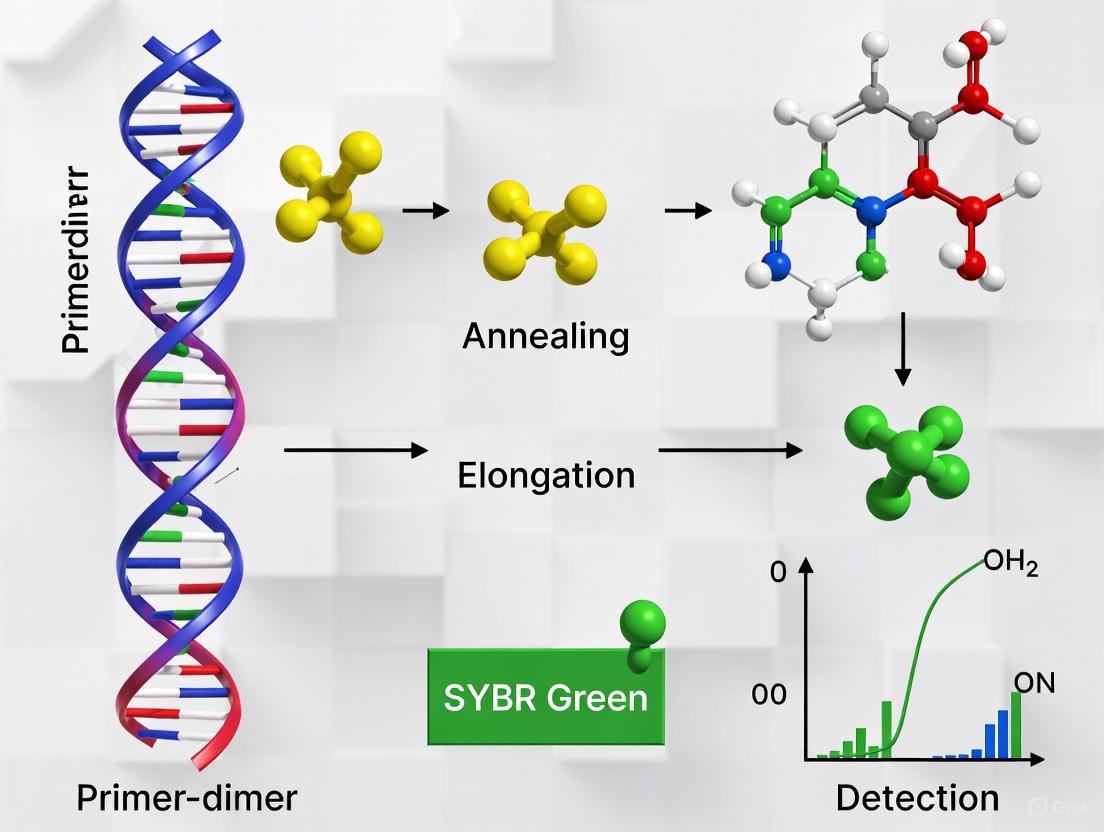

Formation Pathways and Experimental Workflow

The following diagram illustrates the two primary pathways for primer-dimer formation, from initiation to final detection in an assay.

Non-specific amplification is a prevalent challenge in quantitative PCR (qPCR), particularly in SYBR Green assays where the dye binds indiscriminately to any double-stranded DNA. This phenomenon compromises data accuracy by competing with target amplification for reaction resources, potentially leading to both false-positive and false-negative results [6] [17]. Understanding its sources is fundamental to developing robust and reliable qPCR assays, especially in drug development and diagnostic applications where precision is paramount. This guide details the common causes and provides proven solutions for troubleshooting non-specific amplification.

Non-specific amplification in qPCR primarily manifests as primer-dimers or off-target products. The table below summarizes the key sources and their characteristics.

Table 1: Key Sources of Non-Specific Amplification in qPCR

| Source | Description | Common Indicators |

|---|---|---|

| Primer-Dimer Formation [18] [17] | Primers anneal to themselves or each other via complementary regions, forming short, amplifiable artifacts. | - Smear or band below 100 bp on a gel [18] [12].- Additional peak in melt curve analysis at a lower Tm than the target [6] [19].- Amplification in No-Template Control (NTC) [17]. |

| Suboptimal Primer Design [20] | Primers with low specificity or stability, such as those with complementary 3' ends or strong secondary structures. | - Reduced PCR efficiency [20].- Multiple peaks in melt curve analysis [6].- Non-specific bands on a gel [18]. |

| Inadequate Reaction Conditions [21] | Annealing temperature is too low, primer concentration is too high, or the reaction is set up in a way that promotes mis-priming. | - High Cq values for the target [17].- Increased frequency of artifacts at low template concentrations [21]. |

| Template Quality and Concentration [21] [22] | The use of degraded or impure template, or non-optimal template-to-primer ratios. | - Inconsistent results between biological replicates [19].- Smearing on an agarose gel [18]. |

The following diagram illustrates how these primary factors contribute to non-specific amplification and the recommended actions to mitigate them.

Experimental Protocols for Troubleshooting

Protocol: Primer Optimization and Validation

This protocol is designed to identify the optimal primer concentration and annealing temperature to minimize dimerization [20].

Materials:

- Designed primer pairs (e.g., using Primer-BLAST [21])

- SYBR Green I Master Mix

- Validated cDNA or DNA template

- qPCR instrument

Method:

- Checkerboard Primer Titration: Prepare a series of qPCR reactions with varying forward and reverse primer concentrations (e.g., 50 nM, 100 nM, 200 nM, 300 nM) in a cross-fashion [21] [20].

- Annealing Temperature Gradient: Perform a qPCR run using an annealing temperature gradient (e.g., from 55°C to 65°C) for each primer concentration combination.

- Include Controls: Always include a No-Template Control (NTC) for every primer condition to detect primer-dimer formation [19] [17].

- Analysis:

- Analyze amplification curves and Cq values. The optimal condition yields the lowest Cq for the target with the highest fluorescence.

- Perform melt curve analysis. A single, sharp peak indicates specific amplification, while multiple peaks or a peak at a lower temperature suggests non-specific products or primer-dimers [6].

- Select the primer concentration and annealing temperature that give the highest amplification efficiency and specificity (lowest signal in NTC).

Protocol: Assessing the Impact of pipetting Time on Artifacts

This experiment investigates how the time taken to prepare a qPCR plate can influence the formation of early-cycle artifacts [21].

Materials:

- Optimized primer set and master mix

- Template (use a low concentration, as artifacts are more frequent under these conditions [21])

- Ice bucket

- Timer

- qPCR instrument

Method:

- Sample Preparation: Prepare a single master mix containing all reaction components except the template. Keep the mix on ice.

- Simulated Long Bench Time: Aliquot the master mix into two sets of tubes. For the first set, add template and immediately load the reactions into the qPCR instrument and start the run. For the second set, leave the completed reactions on the bench for an extended period (e.g., 45-60 minutes) before loading and starting the run.

- Analysis:

- Compare the Cq values and melt curves of the two sets.

- Reactions with longer bench times often show significantly more artifacts and higher Cq values due to non-specific priming and extension at low temperatures before the PCR cycle begins [21].

Research Reagent Solutions

The following reagents are essential for developing specific and robust SYBR Green qPCR assays.

Table 2: Essential Reagents for Preventing Non-Specific Amplification

| Reagent | Function in Preventing Non-Specific Amplification |

|---|---|

| Hot-Start DNA Polymerase [22] [12] | Enzyme is inactive during reaction setup at room temperature. It is only activated at high temperatures (e.g., 95°C), preventing primer-dimer formation and non-specific extension during plate preparation [21]. |

| SYBR Green I Master Mix [22] | A pre-mixed solution containing optimized buffer, dNTPs, and hot-start polymerase. Using a master mix reduces pipetting steps, improves reproducibility, and minimizes bench time. |

| dNTPs [22] | Deoxynucleoside triphosphates are the building blocks for DNA synthesis. Supplied in a balanced mixture to ensure faithful amplification. |

| MgCl₂ Solution [22] | Magnesium ions are a essential cofactor for DNA polymerase. The concentration can be optimized; lower concentrations often reduce non-specific product formation. |

| Optimized Primer Pairs [21] [20] | Primers designed with stringent criteria (e.g., 40-60% GC content, no 3' complementarity, Tm ~60°C) are the most critical factor for assay specificity. |

| Nuclease-Free Water | A pure, contaminant-free solvent ensures the reaction is not compromised by RNases, DNases, or other inhibitors. |

Frequently Asked Questions (FAQs)

1. My no-template control (NTC) shows amplification. What does this mean? Amplification in your NTC almost always indicates primer-dimer formation [17]. Since no template is present, the signal must be generated by the primers themselves. This is a common source of false-positive results. You should optimize your primer design, reduce primer concentration, or increase the annealing temperature [19] [12].

2. How can I confirm that my melt curve peak is my specific product and not an artifact? A single, sharp peak typically suggests a single, specific product. To confirm, you can run the qPCR product on an agarose gel. A single band at the expected size provides strong corroborating evidence [6]. Sequencing the purified product is the most definitive confirmation.

3. Why do I get non-specific amplification even with primers that worked before? Reproducibility can be affected by subtle changes in workflow. A key, often neglected factor is the time taken to pipette the qPCR plate. Longer bench times can lead to significantly more artifacts, as primers can interact and extend at low temperatures before the run starts, even with hot-start polymerase [21]. Standardize your protocol to minimize bench time and set up reactions on ice.

4. What is the single most important step to avoid non-specific amplification? Meticulous primer design is the most critical preventive step [20]. Using software tools to ensure primers have no self-complementarity, no 3'-end complementarity, and are specific to the target will prevent the majority of non-specific amplification issues. Always validate new primer sets with a melt curve and NTC.

What are primer dimers and how do they form?

Primer dimers are short, nonspecific DNA fragments that are amplified when PCR primers bind to each other instead of to the intended target DNA sequence [17] [14]. This occurs due to minor complementary regions between the primers (cross-dimer) or within a single primer (self-dimer), often at low temperatures before the PCR cycle begins [17]. In SYBR Green assays, the dye binds to all double-stranded DNA (dsDNA), making these artifacts a significant source of error [6] [14].

How do primer dimers lead to false positives and quantification errors?

Primer dimers impact data quality in two primary ways:

- False Positives: SYBR Green dye cannot distinguish between your target amplicon and a primer-dimer product. The fluorescence from amplified primer dimers is detected by the qPCR instrument, leading to a signal in wells that should be negative, such as the No-Template Control (NTC) [17] [14].

- Quantification Inaccuracy: Even in wells with your target DNA, primer-dimer formation competes for reaction resources. This consumption of primers, dNTPs, and polymerase reduces the efficiency of target amplification, leading to higher Ct values, lower calculated template concentrations, and underestimated gene expression levels [17].

The following diagram illustrates the mechanisms through which primer dimers compromise SYBR Green qPCR data.

How can I detect primer dimers in my assay?

Detecting primer dimers is a critical quality control step. The table below summarizes the primary methods.

| Method | Application | Indicator of Primer Dimers |

|---|---|---|

| Melt Curve Analysis [6] [14] | Post-amplification, standard for SYBR Green assays. | Multiple peaks, a low-temperature peak, or broad/asymmetrical peaks on the derivative melt curve. |

| Gel Electrophoresis [14] | Post-amplification analysis. | A fast-migrating, low molecular weight band (typically 50-100 bp) in addition to your target amplicon. |

| No-Template Control (NTC) [17] [23] | Included in every qPCR run. | Amplification in the NTC well, particularly at late Ct values (e.g., beyond cycle 34). |

The workflow for diagnosing primer dimer issues using these methods is as follows:

How can I prevent and troubleshoot primer dimer issues?

Optimize Primer Design and In Silico Testing

Proper primer design is the most effective prevention strategy [15].

- Check Complementarity: Use design software (e.g., Primer3, Primer-BLAST) to ensure primers have no self-complementarity or 3'-end complementarity with their partner (≤3 contiguous bases) [15].

- Optimal Parameters: Design primers 18-25 bp long with a GC content of 40-60% and a Tm between 60-72°C. The Tm for the primer pair should differ by no more than 5°C [15].

Refine Thermal Cycler Conditions

- Use Hot-Start Polymerases: Always use a "hot-start" polymerase enzyme. It remains inactive until a high-temperature step, preventing enzymatic activity during reaction setup at low temperatures where primer dimers form [17] [24].

- Increase Annealing Temperature: Perform a temperature gradient experiment to determine the highest possible annealing temperature that still provides robust, specific amplification [17] [6].

Optimize Reaction Components

- Titrate Primer Concentration: High primer concentrations promote dimerization [17]. Test a range of primer concentrations (typically 50-900 nM) to find the lowest concentration that yields maximum amplification efficiency [24] [25].

- Use Additives: Incorporating additives like BSA (200-400 ng/µL) can help neutralize mild PCR inhibitors that may exacerbate nonspecific amplification [26].

Maintain Rigorous Laboratory Practice

- Prevent Contamination: Use separate work areas for pre- and post-PCR, dedicated equipment, and sterile, filter pipette tips [23] [26].

- Include Proper Controls: Always run an NTC to monitor for contamination and primer-dimer formation [23] [26].

Experimental Protocol: Primer-Dimer Troubleshooting

This protocol provides a systematic approach to diagnose and address primer-dimer problems.

Objective: To identify and minimize primer-dimer formation in a SYBR Green qPCR assay.

Materials & Reagents:

- The Scientist's Toolkit

Reagent/Tool Function High-Quality Primer Pairs Designed with in silico tools to minimize complementarity [15]. Hot-Start SYBR Green ReadyMix Contains hot-start DNA polymerase, SYBR Green dye, dNTPs, and optimized buffer [17] [25]. Nuclease-Free Water Sterile water for preparing reagents and controls, free of nucleases and contaminants [23] [25]. Template cDNA/DNA The target of interest, diluted to an appropriate concentration [25]. No-Template Control (NTC) Reaction mix with nuclease-free water instead of template to check for contamination/primer dimers [23]. qPCR Instrument Instrument capable of real-time fluorescence detection and melt curve analysis [6].

Method:

- Initial Melt Curve Analysis:

- Run your existing assay with both a positive sample and an NTC.

- After amplification, execute the instrument's melt curve protocol (e.g., from 60°C to 95°C).

- Analyze the derivative melt curve. A single sharp peak indicates a specific product. A secondary peak at a lower temperature suggests primer dimers [6].

Primer Re-design (if necessary):

- If dimers are severe, redesign primers using software like Primer-BLAST, focusing on the guidelines in the prevention section above [15].

Annealing Temperature Optimization:

- If primers are well-designed but dimers persist, perform a thermal gradient qPCR.

- Set up identical reactions and run them with an annealing temperature gradient spanning at least 5°C above and below the calculated primer Tm.

- Select the highest temperature that yields the lowest Ct value for the target and no signal in the NTC [6].

Primer Concentration Optimization:

- Test a series of primer concentrations (e.g., 50, 100, 200, 300, 500 nM) while keeping other components constant.

- Identify the concentration that gives the best efficiency and lowest NTC signal [25].

Validation:

- Run the optimized protocol with a fresh set of samples and controls.

- Confirm the absence of primer dimers via melt curve analysis and a clean NTC.

Further Frequently Asked Questions

Q1: Can primer dimers cause false negatives? Yes. While often associated with false positives, primer dimers can also cause false negatives or underestimation of target quantity. They consume reagents (primers, dNTPs, polymerase), leaving fewer resources for amplification of the true target, especially when the target is present at low concentrations [17] [26].

Q2: My probe-based assay has primer dimers. Is this a problem? While probe-based assays (like TaqMan) are more specific because they require probe binding for fluorescence, primer dimers are still problematic. They consume reaction resources, reducing amplification efficiency and leading to higher Ct values and inaccurate quantification [17] [14].

Q3: My NTC shows late amplification (Ct >34). Is this contamination? Late amplification in an NTC is more likely to be caused by primer-dimer amplification than by sample contamination. This should be confirmed with melt curve analysis [23].

Troubleshooting Guides

Guide 1: Diagnosing and Resolving Primer-Dimer Formation

Problem: Primer-dimer formation in SYBR Green qPCR assays leads to reagent waste, experimental delays, and unreliable data.

Background: Primer dimers are artifacts formed when primers anneal to themselves or each other instead of the target DNA template. This is a significant source of economic and time costs in research, consuming valuable reagents and requiring repeated experiments [17].

Symptoms:

- Elevated baseline fluorescence in early PCR cycles

- Multiple or unexpected peaks in melt-curve analysis

- Reduced amplification efficiency of the target gene

- False positives in no-template controls (NTCs)

- Increased Ct values for target amplification, potentially leading to false negatives [6] [17]

Root Causes and Corrective Actions:

| Root Cause | Impact on Experiment | Corrective Action | Economic & Time Benefit |

|---|---|---|---|

| Low Annealing Temperature [17] | Increases non-specific binding and primer-dimer potential. | Optimize annealing temperature: Use temperature gradient PCR to determine the highest possible specific annealing temperature. | Prevents failed runs, saving reagent costs and days of delay. |

| Excessive Primer Concentration [17] | High primer availability promotes intermolecular interactions. | Titrate primer concentrations: Systematically test lower primer concentrations (e.g., 50-300 nM) to find the minimum needed for efficient amplification [8]. | Reduces consumption of expensive primer stocks. |

| Poor Primer Design [6] | Primers with self-complementarity (especially at 3' ends) have a high tendency to form dimers. | Redesign primers: Use design tools to check for hairpins, self-dimers, and cross-dimers. Aim for primers with 40-60% GC content and avoid long stretches of single bases [6]. | Eliminates the root cause, avoiding recurring costs and delays across multiple projects. |

| Suboptimal Reaction Setup | Primer dimers can form at room temperature before PCR initiation. | Use a hot-start polymerase: This enzyme is activated only at high temperatures, preventing low-temperature artifacts [17]. | Improves first-run success rate, conserving master mix and samples. |

Verification of Solution: After implementing corrective actions, run a validation experiment including a no-template control (NTC). A clean NTC with no amplification (or a very late Ct value, e.g., >35) indicates successful suppression of primer-dimers [27] [17]. Melt-curve analysis should show a single, sharp peak corresponding to your specific amplicon [6].

Guide 2: Optimizing SYBR Green Master Mix Usage

Problem: The high cost and occasional scarcity of qPCR master mixes strain research budgets and timelines.

Background: SYBR Green master mix is a primary reagent cost in qPCR. Recent supply chain issues have heightened the need for efficient usage without sacrificing data quality [28].

Symptoms:

- Inability to acquire reagents in a timely manner, halting projects.

- High per-sample cost, limiting experimental scale and statistical power.

- Reagent expiry before a project is completed, leading to waste.

Optimization Strategies:

| Strategy | Application & Methodology | Validation Requirement | Economic & Time Benefit |

|---|---|---|---|

| Using "Past-Expiry" Master Mixes [28] | Methodology: Test master mixes past their official expiry date alongside a new mix using a standardized plasmid or cDNA dilution series. Procedure: Compare Ct values, PCR efficiency (from standard curve), and endpoint fluorescence. | Efficiency should be >90% and ∆Ct vs. new mix should be <0.5 for acceptable performance [28]. | Utilizes otherwise discarded reagents, eliminating replacement costs and procurement wait times. |

| Diluting Master Mix [28] | Methodology: Prepare master mixes at reduced concentrations (e.g., 0.8x, 0.7x, 0.5x) and compare to standard 1x concentration. Procedure: Run a dilution series of template to ensure sensitivity and PCR efficiency are maintained. | PCR efficiency should remain stable. A slight increase in Ct may occur, but detection limit must be acceptable for the assay [28]. | Can extend reagent supply by 30-50%, directly reducing per-sample cost and increasing testing capacity. |

| Fast Cycling Protocols | Methodology: Use modern "fast" cycling protocols with shortened denaturation and extension steps. Procedure: Adapt the protocol according to the instrument and master mix capabilities. Validate with a standard curve. | Must confirm that amplification efficiency and sensitivity are equivalent to the standard protocol. | Increases instrument throughput, freeing up machines and reducing labor costs per run. |

Frequently Asked Questions (FAQs)

Q1: My no-template control (NTC) shows amplification with a low Ct value. Does this mean my master mix is contaminated? Not necessarily. While contamination is one possibility, a more common cause for a low Ct in the NTC is primer-dimer formation [17]. To diagnose this, perform melt-curve analysis. A primer-dimer product will typically have a lower melting temperature (Tm) than your specific amplicon, appearing as a separate, early peak [6]. Contamination with target DNA would produce a peak identical to your positive sample.

Q2: My melt curve has one main peak, but it is very broad or has a shoulder. What does this indicate? A broad peak or a shoulder on the main peak suggests the presence of multiple, similar-sized amplification products. This could be due to non-specific amplification where your primers are binding to unintended genomic sequences. It can also indicate the presence of primer-dimers that are not fully resolved from your main product [6]. You should optimize primer concentration and annealing temperature, or consider redesigning your primers for greater specificity.

Q3: I am using "hot-start" polymerase, but I still get primer dimers. Why? While hot-start polymerase prevents enzyme activity during reaction setup, it does not prevent the physical annealing of the primers to each other at low temperatures [17]. These primer duplexes can then be efficiently extended in the first PCR cycle once the enzyme is activated. The solution is to address the root cause: improve primer design and optimize reaction conditions.

Q4: Is it scientifically valid to use a master mix that is past its expiry date? Yes, provided it is empirically validated for your specific assay. Research shows that many master mixes perform robustly for months or even years past their printed expiry date if stored properly [28]. The key is to run a validation experiment comparing the old and new mixes to confirm that PCR efficiency, sensitivity, and dynamic range have not significantly degraded.

Q5: How can I distinguish between different amplification products in a SYBR Green assay? The primary method is meltencurve analysis. Each unique DNA amplicon has a specific melting temperature (Tm) based on its length, GC content, and sequence [6]. This is visualized as a distinct peak. For example, a study detecting tick-borne pathogens used Tm values to differentiate between Babesia bigemina (74.38°C) and Theileria orientalis (74.61°C) [29]. Always confirm the identity of unexpected peaks with gel electrophoresis.

Research Reagent Solutions

The following table details key reagents and strategies for optimizing SYBR Green assays to mitigate economic loss.

| Item / Solution | Function in the Assay | Optimization Guidance to Reduce Waste |

|---|---|---|

| SYBR Green Master Mix | Contains DNA polymerase, dNTPs, buffer, and the fluorescent dye that binds dsDNA. The core reagent for the reaction. | Validate performance at diluted concentrations (e.g., 0.5x) and with "past-expiry" batches to extend supplies [28]. |

| Primers | Short DNA sequences designed to flank and define the target region for amplification. | Titrate concentration (50-300 nM) to find the minimum required. Careful in-silico design is crucial to avoid dimerization and reduce need for repeats [17] [8]. |

| Template DNA/cDNA | The nucleic acid sample containing the target sequence to be amplified and quantified. | Use a crude but effective extraction method where possible, balancing cost, time, and required purity for the assay [8]. |

| Hot-Start Polymerase | A modified enzyme activated only at high temperatures, preventing non-specific amplification and primer-dimer formation during reaction setup [17]. | A critical investment to improve first-attempt success rates, saving on total reagent consumption and researcher time. |

| No-Template Control (NTC) | A control reaction containing all reagents except the template DNA, used to detect contamination or primer-dimer formation. | An essential quality control step. A clean NTC validates the entire reaction setup, preventing wasted samples and erroneous data [6] [17]. |

Experimental Workflow and Protocols

Detailed Protocol: Primer-Dimer Troubleshooting and Assay Validation

This protocol provides a step-by-step method to diagnose and address primer-dimer formation.

Step 1: Assay Design and In-Silico Analysis

- Design Primers using specialized software (e.g., Primer3) and validate specificity with NCBI Primer-BLAST [27] [8].

- Check for Self-Complementarity: Analyze primers for hairpins, self-dimers, and cross-dimers using oligo analyzer tools. Pay special attention to the 3' ends, as even a few complementary bases can initiate dimer formation [17].

Step 2: Initial Singleplex Optimization

- Test Primer Sets Individually: Perform SYBR Green qPCR with each primer set alone, using both a positive sample (known template) and a no-template control (NTC) [8].

- Analyze Results:

- Amplification Plot: The positive sample should show a clean, exponential curve. The NTC should have no amplification or a very late Ct (>35).

- Melt Curve: The positive sample should produce a single, sharp peak. Any peak in the NTC is indicative of primer-dimer [6].

Step 3: Reaction Condition Optimization If primer-dimer is observed:

- Perform a Temperature Gradient: Test a range of annealing temperatures (e.g., 55°C to 65°C) to find the highest temperature that provides specific amplification without dimers [6].

- Titrate Primer Concentration: Test a range of primer concentrations (e.g., from 50 nM to 600 nM) against a template dilution series to find the lowest concentration that yields efficient amplification without increasing dimer formation [8].

Step 4: Final Validation with Multiplexing (if applicable)

- Once each primer set is optimized individually, combine them for a multiplex reaction [8].

- Re-run the assay with positive samples and NTCs.

- Confirm that the melt curve shows distinct, specific peaks for each amplicon and that the NTC is clean.

The following diagram illustrates the logical workflow for diagnosing and resolving primer-dimer issues.

Strategic Assay Design and Melting Curve Analysis for Reliable Detection

This guide provides a focused troubleshooting resource for researchers developing SYBR Green-based qPCR assays. A primary challenge in this process is ensuring that primers specifically amplify the intended target without forming primer-dimers or other artifacts that compromise data accuracy. The following sections address specific, common problems and provide validated solutions to enhance the specificity and reliability of your experiments.

Frequently Asked Questions (FAQs)

1. Why do my SYBR Green assays sometimes produce false positive results?

False positives in SYBR Green assays are frequently caused by primer-dimer formation or non-specific amplification. Since the SYBR Green dye binds to any double-stranded DNA, it cannot distinguish between your target amplicon and these byproducts. This can lead to the detection of an ascending fluorescence signal in no-template controls (NTCs), indicating a false positive [6] [17]. The solution is to perform melt-curve analysis after the qPCR run to confirm that a single, specific product was amplified.

2. How can a primer with a good in silico design still perform poorly in practice?

Theoretical primer design is a starting point, but performance must be validated empirically. Poor performance can stem from several issues:

- Unoptimized Annealing Temperature: The calculated melting temperature (Tm) may not match the optimal annealing temperature (Ta) for your specific reaction conditions, including the master mix and thermal cycler used [9] [30].

- Unexpected Mismatches: Even a single base mismatch, especially in the 3'-end of the primer, can severely reduce amplification efficiency. The impact is highly dependent on the type of mismatch and its position [30].

- Reaction Component Interference: Components like high salt concentrations can inhibit polymerase activity [31].

3. What are the critical parameters to check first when troubleshooting failed amplification?

First, verify the fundamental design features of your primers [32] [33]:

- Primer Length: 18-30 nucleotides.

- Melting Temperature (Tm): 60-75°C, with forward and reverse primers within 5°C of each other.

- GC Content: Between 40% and 60%.

- GC Clamp: The 3'-end should end in a G or C base, but avoid runs of multiple Gs or Cs.

- Secondary Structures: Check for self-dimers, cross-dimers, and hairpins.

Troubleshooting Guides

Problem 1: Non-Specific Amplification and Multiple Peaks in Melt Curve

A melt curve with multiple peaks, broad peaks, or shoulders indicates that more than one double-stranded DNA product is present in the reaction [6].

Investigation and Resolution:

- Step 1: Confirm the Results. Run the qPCR products on an agarose gel. A single, sharp band at the expected size confirms a specific product, while multiple bands confirm non-specific amplification [6].

- Step 2: Increase Annealing Temperature. Raise the annealing temperature in 1-2°C increments. Higher temperatures favor specific primer binding and can disrupt the weaker binding of primers to off-target sequences [6] [33].

- Step 3: Redesign Primers. If optimization fails, redesign the primers. Use BLAST analysis to ensure they are unique to your target and avoid sequences with high inter-primer homology or regions of secondary structure [9] [33].

Problem 2: Primer-Dimer Formation

Primer-dimers are short, double-stranded artifacts formed when primers anneal to themselves or each other. They consume reaction reagents and generate false positive signals in SYBR Green assays, potentially leading to false negatives for low-abundance targets [17].

Investigation and Resolution:

- Step 1: Identify Primer-Dimers. In the melt curve, primer-dimers typically appear as a peak at a lower temperature than the main amplicon peak. They are also often visible in no-template controls (NTCs) [6] [17].

- Step 2: Optimize Primer Concentration. High primer concentrations increase the likelihood of primers interacting with each other. Test a range of primer concentrations (e.g., 50-500 nM) to find the lowest concentration that still provides robust amplification of the target [17].

- Step 3: Use a Hot-Start Polymerase. Hot-start enzymes remain inactive until a high-temperature activation step, preventing enzymatic activity during reaction setup when primer-dimer formation is most likely to occur [17].

- Step 4: Redesign Primers. Check primers for self-complementarity, especially at their 3'-ends. Avoid complementary sequences between the forward and reverse primers. Design tools can calculate the ΔG for dimers; aim for values weaker (more positive) than -9.0 kcal/mol [33].

Problem 3: Low Amplification Efficiency or No Amplification

This problem can arise from primers failing to bind or extend from the template efficiently.

Investigation and Resolution:

- Step 1: Check for Primer-Template Mismatches. Mismatches at the 3'-end of a primer, particularly at the ultimate (last) base, can dramatically reduce PCR efficiency. The effect varies by mismatch type; for example, A-A or G-A mismatches have a severe impact, while A-C mismatches are more tolerated [30].

- Step 2: Lower the Annealing Temperature. If the annealing temperature is too high, primers may not bind to the template at all. Lower the temperature in increments, but be aware that this may increase non-specific amplification [33].

- Step 3: Verify Template Quality and Concentration. Ensure the template is intact and free of inhibitors. Use a higher amount of input cDNA, but do not exceed 20% of the total reaction volume [34].

Experimental Protocols

Protocol 1: Systematic Primer Validation using SYBR Green qPCR

This protocol is essential for verifying primer specificity and optimal function before processing valuable samples [6] [17].

- Reaction Setup: Prepare a standard SYBR Green qPCR master mix according to manufacturer instructions. Include a no-template control (NTC) containing nuclease-free water instead of cDNA.

- Thermal Cycling: Run the qPCR with a standard cycling protocol (e.g., 2 min at 50°C, 10 min at 95°C, followed by 40 cycles of 15 sec at 95°C and 60 sec at 60°C).

- Melt Curve Analysis: After amplification, run a melt curve analysis from 60°C to 95°C.

- Data Interpretation:

- A single sharp peak in the melt curve indicates specific amplification.

- A clean NTC (no amplification or a late Ct value with a low-temperature melt peak) indicates minimal primer-dimer formation.

- Multiple peaks or a peak in the NTC requires further optimization or redesign.

Protocol 2: Empirical Determination of Optimal Annealing Temperature

Theoretical Tm calculations are a guide; the true optimal Ta must be determined experimentally [9].

- Design a Gradient: Set up identical qPCR reactions and use the thermal cycler's temperature gradient function across a range (e.g., 55°C to 65°C).

- Run the qPCR: Amplify the reactions using the gradient.

- Analyze Results: The optimal annealing temperature is the highest temperature that yields the lowest Ct value and the highest fluorescence (ΔRn) for the specific amplicon. An assay that works well over a broad temperature range (e.g., >4°C) is considered robust [9].

Data Presentation

Table 1: Quantitative Impact of 3'-End Primer-Template Mismatches

This table summarizes the effect of single-nucleotide mismatches on PCR efficiency, measured by the delay in Cycle threshold (Ct) value. Data is based on a study using specific 5'-nuclease assay master mixes [30].

| Mismatch Type (Primer:Template) | Position from 3'-End | Average Ct Delay (Cycles) | Severity Classification |

|---|---|---|---|

| A-A | 1 (terminal) | >7.0 | Severe |

| G-A | 1 (terminal) | >7.0 | Severe |

| C-C | 1 (terminal) | >7.0 | Severe |

| A-G | 1 (terminal) | >7.0 | Severe |

| A-C | 1 (terminal) | <1.5 | Minor |

| C-A | 1 (terminal) | <1.5 | Minor |

| T-G | 1 (terminal) | <1.5 | Minor |

| G-T | 1 (terminal) | <1.5 | Minor |

Table 2: Optimal Primer and Probe Design Parameters

These guidelines consolidate recommended parameters for designing effective PCR primers and hydrolysis probes [32] [33].

| Parameter | PCR Primer Guidelines | qPCR Probe Guidelines |

|---|---|---|

| Length | 18–30 bases | 20–30 bases (for single-quenched) |

| Melting Temp (Tm) | 60–75°C; ideally 62°C | 5–10°C higher than primers |

| Annealing Temp (Ta) | 5°C below the primer Tm | N/A |

| GC Content | 40–60%; ideal 50% | 35–65% |

| GC Clamp | 1-2 G or C bases at the 3'-end | Avoid G at the 5'-end |

| Specificity | Avoid runs of ≥4 identical bases; check for dimers (ΔG > -9 kcal/mol) | Should not overlap primer-binding site |

Workflow Visualization

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions

| Item | Function |

|---|---|

| Hot-Start DNA Polymerase | Prevents enzymatic activity at low temperatures, reducing primer-dimer formation [17]. |

| SYBR Green Master Mix | Provides all components for qPCR, including the fluorescent dye that binds dsDNA [6]. |

| RNase Inhibitor | Protects RNA templates and cDNA synthesis reactions from degradation by RNases [31]. |

| dNTPs | The building blocks (dATP, dCTP, dGTP, dTTP) required for DNA synthesis by the polymerase. |

| MgCl₂ Solution | A critical cofactor for polymerase activity; concentration often requires optimization. |

This article provides a comprehensive technical guide on melting curve analysis, a critical post-amplification step in quantitative PCR (qPCR) that verifies the specificity of SYBR Green assays. It addresses the common challenge of primer-dimer formation and other non-specific amplification artifacts, offering detailed troubleshooting guides, FAQs, and standardized protocols to ensure data integrity for researchers and drug development professionals.

Foundational Principles of Melting Curve Analysis

Melting curve analysis is an assessment of the dissociation characteristics of double-stranded DNA during heating. This method is a fundamental quality control step in experiments using intercalating dyes like SYBR Green. [35]

The Principle of DNA Dissociation: When double-stranded DNA (dsDNA) is heated, it denatures into single strands in a process often called "melting." The melting temperature (Tm) is defined as the temperature at which 50% of the DNA is denatured. This Tm is a unique property of a DNA sequence, determined by its length, GC content, and sequence complementarity. Guanine-cytosine (G-C) base pairs, with three hydrogen bonds, contribute to a higher Tm than adenine-thymine (A-T) pairs, which have only two. Consequently, any single-nucleotide polymorphism (SNP) that changes an A-T pair to a G-C pair (or vice versa) will alter the Tm of the resulting amplicon. [35] [36]

The Role of SYBR Green: SYBR Green is a fluorescent dye that intercalates into the minor groove of double-stranded DNA. When bound, its fluorescence increases dramatically—up to 1000-fold. As the temperature in the qPCR instrument is raised after amplification (typically from 60°C to 95°C), the dsDNA products denature, releasing the SYBR Green dye and causing a sharp decrease in fluorescence. By plotting this change in fluorescence against temperature, a melting curve is generated. The negative first derivative of this curve is often used to produce distinct peaks, where each peak represents a specific DNA product with a characteristic Tm. A single, sharp peak typically indicates amplification of a single, specific PCR product. The presence of multiple peaks, broad peaks, or shoulders on a peak suggests issues such as primer-dimer formation or non-specific amplification. [6] [35]

Application in Quality Control: The nonspecific nature of SYBR Green binding makes melt-curve analysis an indispensable quality control step. Since the dye fluoresces upon binding to any dsDNA—including primer dimers and non-specific amplicons—it is crucial to confirm that the detected fluorescence originates primarily from the intended target. Without this verification, quantitative results (such as Ct values) for gene expression can be severely compromised. [6]

Troubleshooting Guide: FAQs on Melt Curve Anomalies

This section addresses the most common challenges researchers face when interpreting melt curve data in SYBR Green qPCR assays.

FAQ 1: What causes multiple peaks in my melt curve analysis? Multiple peaks typically indicate the presence of more than one distinct double-stranded DNA species in your reaction. The two primary sources are:

- Non-specific amplification: This occurs when your primers bind to and amplify off-target sequences. This can be due to low primer annealing specificity. [6]

- Primer-dimer formation: This is the most common cause. Primer-dimers form when primers anneal to themselves or to each other, leading to the amplification of a very short, unintended product. These dimers have a low Tm, usually resulting in a peak at a lower temperature than your specific amplicon. [6]

FAQ 2: How can I distinguish a primer-dimer peak from a specific product peak? Primer-dimers are typically short PCR products and thus have a lower melting temperature (Tm) than your longer, specific amplicon. In a derivative melt curve, primer-dimers will appear as a distinct peak at a lower temperature (e.g., 75-80°C or lower). The specific amplicon will produce a peak at a higher, expected Tm. The presence of a low-temperature peak is a strong indicator of primer-dimer formation. [6] [36]

FAQ 3: My melt curve shows a single peak, but my qPCR efficiency is low. Can I trust the data? A single peak suggests that a single product was amplified, but it does not prove that it is the correct product. The single peak could be a result of predominant primer-dimer formation or a single, but non-specific, amplicon. To confirm the identity of your product, you should run the PCR product on an agarose gel. A single, sharp band of the expected size provides further evidence that a single, specific product was amplified. Low efficiency could be related to poor primer design, reaction conditions, or cDNA quality. [6]

FAQ 4: What steps can I take to reduce primer-dimer formation? Several experimental adjustments can help mitigate primer-dimer formation:

- Optimize primer concentration: Reducing the concentration of primers in the reaction can deter dimer formation. [6]

- Increase annealing temperature: A higher annealing temperature during PCR cycling promotes stricter primer binding, reducing the chance of primers annealing to non-target sequences or to each other. [6]

- Redesign primers: If optimization fails, redesigning the primers to increase their specificity and reduce self-complementarity (especially at the 3' ends) is often necessary. [6]

- Use advanced design algorithms: For highly multiplexed assays, computational tools like SADDLE (Simulated Annealing Design using Dimer Likelihood Estimation) can design primer sets that minimize the likelihood of primer-dimer interactions across hundreds of primers. [37]

FAQ 5: What do unusually wide or asymmetrical peaks indicate? Unusually wide, asymmetrical, or "shouldered" peaks suggest a more complex problem. They can indicate the presence of multiple products with very similar but not identical Tm values, which the instrument's software cannot fully resolve. This could be due to a mixture of specific and non-specific products, or amplification from a sequence with multiple splice variants. These anomalies often merit re-optimizing the assay, checking instrument calibration, or potentially redesigning the experiment. [6]

Standard Operating Procedures (SOPs)

Protocol for Performing Melt Curve Analysis

This protocol follows the amplification step in a SYBR Green qPCR run.

Step 1: Set Up the Instrument Method. After the final PCR cycle, program the real-time PCR instrument to run a melt curve. A standard protocol is:

- Hold: 95°C for 15 seconds (to fully denature all products).

- Annealing/Cooling: 60°C for 1 minute (to allow for re-annealing).

- Melt/Melting Curve: Gradually increase the temperature from 60°C to 95°C at a continuous rate (e.g., 0.1°C to 0.5°C per second) while continuously monitoring the fluorescence. [6] [38]

Step 2: Data Collection. The instrument's software will collect fluorescence data across the entire temperature ramp.

Step 3: Data Analysis.

- View the raw fluorescence vs. temperature plot to observe the overall dissociation.

- Switch to the negative first derivative view of the melting curve. This transformation converts the gradual drop in fluorescence into distinct peaks, making interpretation more straightforward. [35]

- Identify the Tm value(s) for the peak(s), which corresponds to the temperature at the peak's maximum.

Step 4: Interpretation and QC.

- A single, sharp peak indicates a single, specific PCR product.

- Multiple peaks indicate multiple products (e.g., specific amplicon and primer-dimers).

- Compare the Tm of your peak to the expected Tm of your target amplicon.

Protocol for Agarose Gel Confirmation of Specific Amplification

This is a confirmatory step for any new SYBR Green assay.

Step 1: Prepare an Agarose Gel. Prepare a standard 1.5% - 2% agarose gel in 1x TAE or TBE buffer, stained with a DNA intercalating dye like ethidium bromide or a safer alternative.

Step 2: Load and Run the Samples.

- Combine a portion of your post-qPCR reaction (e.g., 5-10 µL) with DNA loading dye.

- Load the mixture into the gel wells alongside an appropriate DNA ladder.

- Run the gel at a constant voltage (e.g., 100V) until the dye front has migrated sufficiently.

Step 3: Visualize and Interpret.

- Visualize the gel under UV light.

- A single, clean band at the expected amplicon size confirms target specificity. [6]

- A bright, fast-migrating band near the bottom of the gel (typically around 20-50 bp) indicates significant primer-dimer formation.

Data Interpretation and Presentation

Characteristic Melt Curve Profiles and Their Interpretation

The following table summarizes common melt curve profiles and their diagnostic meanings for quality control.

Table 1: Interpretation of Common Melt Curve Profiles in SYBR Green qPCR

| Melt Curve Profile | Description | Probable Cause | Recommended Action |

|---|---|---|---|

| Single, Sharp Peak | A single, symmetrical derivative peak. | Single, specific amplicon. Ideal outcome. | Proceed with data analysis. |

| Two Distinct Peaks | A higher Tm peak and a lower Tm peak (~75-80°C). | Specific product + primer-dimers. The low-Tm peak is primer-dimer. | Optimize primer concentrations or annealing temperature; consider primer redesign. |

| Multiple Peaks | More than two peaks across the temperature range. | Multiple non-specific products and/or severe primer-dimer formation. | Redesign primers; check primer specificity using BLAST. |

| Broad or "Shouldered" Peak | A single but wide peak, or a peak with a shoulder. | Co-melting of multiple products with very similar Tm, or a heterogeneous product. | Optimize PCR conditions; run agarose gel for confirmation; consider increasing annealing temperature. |

The Researcher's Toolkit: Essential Reagents and Materials

Table 2: Key Research Reagent Solutions for SYBR Green qPCR and Melt Curve Analysis

| Item | Function/Description | Example/Note |

|---|---|---|

| SYBR Green Dye | Intercalating fluorescent dye that binds dsDNA. Signal increases 1000-fold upon binding. | Included in most commercial SYBR Green master mixes. [6] |

| High-Quality Primers | Oligonucleotides designed for high specificity and minimal self-complementarity. | Tools like SADDLE algorithm can design low-dimer multiplex primer sets. [37] |

| cDNA Synthesis Kit | Converts RNA to cDNA for gene expression studies. | Reverse transcriptase can introduce bias; assess cDNA quality with standard curves. [6] |

| Hot-Start DNA Polymerase | Reduces non-specific amplification and primer-dimer formation by remaining inactive until the first high-temperature step. | A common component of robust qPCR master mixes. |

| Saturation Dyes (for HRM) | Dyes that saturate dsDNA without inhibiting PCR, enabling high-resolution melting (HRM) for SNP detection. | Examples include LCGreen. [38] |

Workflow and Conceptual Diagrams

Experimental Workflow for SYBR Green QC

The diagram below outlines the complete workflow from assay design to data validation, highlighting key quality control checkpoints.

Interpreting Melt Curve and Derivative Plot

This diagram illustrates the relationship between the raw melt curve and its derivative plot, and how to diagnose common issues.

Optimized Thermal Cycling Conditions to Minimize Non-Specific Binding

In SYBR Green qPCR assays, the fluorescence dye binds non-specifically to any double-stranded DNA, making the technique highly susceptible to non-specific amplification and primer-dimer formation. These artifacts can severely compromise data accuracy by competing for reaction components and generating false fluorescence signals. This guide provides targeted thermal cycling strategies and troubleshooting methodologies to help researchers eliminate non-specific binding, ensuring the integrity of their gene expression and quantification data.

Frequently Asked Questions (FAQs)

1. Why does my SYBR Green qPCR assay produce multiple peaks in the melt curve? Multiple peaks in a melt curve analysis typically indicate the presence of more than one amplification product, such as non-specific PCR products or primer-dimers [6]. A single, sharp peak is characteristic of a specific, pure amplicon. Shoulders on a main peak or unusually wide peaks also suggest that primer-dimers have formed or that non-specific amplification has occurred.

2. How can I adjust thermal cycling conditions to reduce primer-dimer formation? Primer-dimer formation often occurs when the annealing temperature is too low, allowing primers to bind non-specifically to each other [39] [40]. Increasing the annealing temperature improves specificity by ensuring primers bind only to their intended target sequences [39] [41]. Using a "hot-start" DNA polymerase is also recommended, as it prevents enzymatic activity at low temperatures during reaction setup, thereby reducing non-specific amplification [42] [39].

3. What is a "no-template control" (NTC) and why is it essential? An NTC is a reaction that contains all the master mix components and primers but uses nuclease-free water instead of template DNA [43]. It is a critical control to check for contamination in your reagents. Amplification in the NTC indicates the presence of contaminating DNA or significant primer-dimer formation, which could lead to false positives in your actual samples.

4. My amplification is inefficient. Could thermal cycling be a factor? Yes, suboptimal denaturation, annealing, or extension steps can all lead to poor efficiency [39]. Insufficient denaturation can prevent the DNA strands from separating completely, while an incorrect annealing temperature can reduce primer binding efficiency. Furthermore, if the extension time is too short for your amplicon's length, the polymerase may not fully copy the target, leading to reduced yield. Ensure your cycling conditions are optimized for your specific primer set and amplicon.

Troubleshooting Guide: Non-Specific Binding and Primer-Dimer Formation

Table: Troubleshooting Common SYBR Green qPCR Issues

| Observation | Possible Cause | Recommended Solution |

|---|---|---|

| Multiple peaks on melt curve | Non-specific amplification; Primer-dimer formation [6] | Increase annealing temperature [39] [41]; Redesign primers; Use touchdown PCR [40] |

| Smearing or multiple bands on gel | Non-specific products; Incorrect Mg2+ concentration [39] | Optimize Mg2+ concentration (0.2-1 mM increments) [41]; Use hot-start polymerase [39] |

| Low reaction efficiency | Suboptimal annealing temperature; Poor primer design [39] | Recalculate primer Tm; Use a gradient cycler to test annealing temperatures (1-2°C increments) [39] [44] |

| False positive in NTC | Contaminated reagents; Excessive primer-dimer formation [43] | Prepare fresh reagents and aliquots; Increase annealing temperature; Optimize primer concentrations [40] |

Optimized Thermal Cycling Protocols

Standard qPCR Protocol with SYBR Green

A standard protocol is a starting point for optimization. The following table outlines a common cycling setup [43].

Table: Standard SYBR Green qPCR Cycling Conditions

| Step | Temperature | Time | Cycles | Purpose |

|---|---|---|---|---|

| Initial Denaturation | 95°C | 2-10 minutes | 1 | Activate hot-start polymerase; fully denature complex DNA [42] |

| Denaturation | 95°C | 15-30 seconds | 40 | Separate double-stranded DNA amplicons from previous cycle |

| Annealing | 55-65°C* | 30 seconds | 40 | Allow primers to bind specifically to the template |

| Extension | 72°C | 30 seconds | 40 | Synthesize new DNA strands (time depends on amplicon length) |

| Melt Curve | 60°C to 95°C | Incremental increase (e.g., 0.5°C/step) | 1 | Analyze amplicon specificity [6] |

*The optimal annealing temperature must be determined experimentally.

Advanced Protocol: Touchdown PCR

Touchdown PCR is a highly effective method for increasing specificity and minimizing non-specific binding and primer-dimers, especially when setting up a new assay [40].

Methodology:

- Initial High-Temperature Annealing: Begin with an annealing temperature 5-10°C above the calculated Tm of your primers.

- Gradual Temperature Reduction: Over the subsequent cycles, decrease the annealing temperature in increments of 0.5-1°C per cycle until you reach the final, calculated annealing temperature.

- Final Amplification: Continue with 10-15 additional cycles at this final, lower annealing temperature.

Rationale: In the early cycles, the high annealing temperature permits only the most specific primer-template binding to occur. These specific products are then amplified exponentially in the later cycles, effectively out-competing any non-specific products that might form at the lower temperatures.

Key Optimization Strategies

- Annealing Temperature Optimization: The most critical parameter. Use a gradient thermal cycler to test a range of annealing temperatures (e.g., from 55°C to 65°C) in a single run. The optimal temperature is typically 3-5°C below the primer Tm [39] [44]. Select the temperature that yields the lowest Cq and a single peak in the melt curve.

- Mg2+ Concentration Titration: Mg2+ is a cofactor for DNA polymerase, and its concentration can dramatically affect specificity [42] [41]. Excess Mg2+ can stabilize non-specific primer binding. Test Mg2+ concentrations in 0.2 mM to 1.0 mM increments to find the concentration that gives the highest yield of specific product [41].

- Melt Curve Analysis: This is a non-negotiable quality control step for SYBR Green assays [6]. After amplification, the temperature is gradually increased from around 60°C to 95°C while continuously monitoring fluorescence. A single, sharp peak in the derivative melt curve indicates a single, specific PCR product. Multiple peaks, broad peaks, or shoulders indicate non-specific amplification or primer-dimer formation.

Experimental Workflow and Visualization

The following diagram illustrates a logical workflow for optimizing thermal cycling conditions to minimize non-specific binding.

Diagram 1: Thermal Cycling Optimization Workflow

The melt curve analysis is a critical diagnostic step. The diagram below shows how to interpret the results.

Diagram 2: Interpreting Melt Curve Results

The Scientist's Toolkit: Essential Reagents and Materials

Table: Key Reagents for SYBR Green qPCR Optimization

| Reagent/Material | Function | Optimization Consideration |

|---|---|---|

| Hot-Start DNA Polymerase | Reduces non-specific amplification and primer-dimer formation by being inactive at room temperature [39]. | Essential for high-specificity assays. Prevents mis-priming during reaction setup. |

| SYBR Green I Dye | Fluorescent dye that intercalates into double-stranded DNA, allowing for real-time quantification [6]. | Concentration can affect melt curve profiles; avoid limiting dye in multiplex attempts [45]. |

| dNTP Mix | Building blocks for new DNA synthesis. | Use balanced equimolar concentrations to prevent misincorporation [41]. |

| Magnesium Chloride (MgCl₂) | Cofactor essential for DNA polymerase activity [42] [41]. | Concentration critically impacts specificity; must be titrated for each assay [39] [41]. |

| Primers | Sequence-specific oligonucleotides that define the target amplicon. | Design is paramount. Avoid 3'-end complementarity to prevent primer-dimers [44]. |

| PCR Additives (e.g., DMSO, Betaine) | Can help denature templates with high GC-content or secondary structures [39] [44]. | Use at the lowest effective concentration as they can inhibit polymerase if in excess [39]. |

Frequently Asked Questions (FAQs)

Q1: Why is an internal control necessary in a SYBR Green qPCR assay? An internal control is crucial to verify that the entire qPCR reaction—from nucleic acid extraction to amplification—has functioned correctly. It helps distinguish a true negative result from a false negative caused by reaction failure, the presence of inhibitors, or errors in pipetting [27] [46]. In SYBR Green assays, which use a dye that binds to any double-stranded DNA, confirming the amplification of the intended target is especially important [6] [46].

Q2: How can I tell if my internal control is working properly? A properly functioning internal control should amplify within a consistent and expected Cycle threshold (Ct) range in your validated protocol. You should observe a single, sharp peak at the expected melting temperature (Tm) for the internal control product during melt-curve analysis [6]. A significantly delayed Ct value or an abnormal melt curve peak for the internal control indicates a problem with the reaction that invalidates the results for your target of interest.

Q3: What are the consequences of a poorly optimized internal control? A poorly optimized internal control can compete with the target gene for reaction components, leading to reduced sensitivity and efficiency for your primary assay [47]. If the primers for the internal control form primer-dimers, the SYBR Green dye will bind to these non-specific products, generating a false fluorescent signal that can be misinterpreted during analysis [12] [47].

Q4: My internal control failed to amplify. What should I check? First, verify the integrity and concentration of the internal control template. Next, check for the presence of PCR inhibitors in your sample and confirm that you are using the correct primer concentrations. Finally, ensure that the thermal cycler conditions, particularly the annealing temperature, are optimal for the internal control primer set [47] [48].

Q5: Can I use the same internal control for different sample types? The suitability of an internal control can vary by sample type. The control must be validated for each specific sample matrix (e.g., blood, tissue, swab samples) to ensure it amplifies reliably and consistently without being affected by matrix-specific inhibitors [46].

Troubleshooting Guide: Common Issues with Internal Controls

| Problem | Potential Causes | Recommended Solutions |

|---|---|---|

| No Amplification of Internal Control | PCR inhibitors in the sample, degraded template, incorrect reagent concentrations, or instrument error [46]. | Include a positive control with a known template. Check DNA/RNA quality, dilute sample to reduce inhibitors, and verify reagent preparation [47]. |

| Inconsistent Ct Values | Pipetting errors, uneven reagent mixing, or low-quality nucleic acid extracts [47]. | Ensure thorough mixing of reagents, calibrate pipettes, and re-extract nucleic acids to ensure purity and consistency. |

| Multiple Peaks in Melt Curve | Non-specific amplification or primer-dimer formation [6] [12]. | Optimize primer concentrations and annealing temperature. Use a hot-start DNA polymerase and validate primer specificity [47]. |

| Internal Control Ct is Too High | Low concentration of internal control template, suboptimal primer efficiency, or partial reaction inhibition [47]. | Titrate the internal control to an optimal concentration and re-optimize primer annealing conditions [47]. |

| Internal Control Outcompetes Target | The concentration of the internal control is too high relative to the target [47]. | Lower the concentration of the internal control primers or template to minimize competition for reaction resources [47]. |

Quantitative Data from SYBR Green Assays

The following table summarizes key performance metrics from published SYBR Green assays, illustrating typical values for a well-optimized system that includes controls.

| Study / Application | Target Genes | Internal Control | Limit of Detection | Melting Temp (Tm) Range |

|---|---|---|---|---|

| Detecting Tick-Borne Pathogens [29] | Babesia and Theileria spp. | Not specified | 10 copies/μL | 74.06°C - 75.84°C |

| Detecting Carbapenem Resistance [27] | blaKPC, blaNDM-1, blaOXA-48 | 16S rRNA | 10 - 10² DNA copies/mL | 80.67°C - 90.65°C |

| Detecting SARS-CoV-2 [46] | N gene of SARS-CoV-2 | Human RNase P (in comparator TaqMan kit) | Comparable to commercial kit | Single, specific peak confirmed |

Experimental Protocol: Validating Reaction Efficiency with an Internal Control

Objective: To integrate and validate a housekeeping gene as an internal control in a SYBR Green qPCR assay, ensuring it amplifies with high efficiency without interfering with the primary target.

Materials:

- Template DNA/RNA: Extracted from test samples.

- Primers: Specific primers for both the target gene and the internal control gene (e.g., GAPDH, β-actin, 16S rRNA).

- SYBR Green Master Mix: Contains DNA polymerase, dNTPs, buffer, and SYBR Green dye [49].

- Nuclease-free Water.

- qPCR Instrument with melt-curve analysis capability.

Methodology:

- Primer Design and Validation:

- Design primers for the internal control following the same stringent rules as for the target gene. Use software like Primer-BLAST to ensure specificity [46] [48].

- Analyze sequences for self-complementarity and potential for primer-dimer formation. Avoid primers with strong 3'-end complementarity (ΔG < -2.0 kcal/mol) [47].

Optimization of Primer Concentration:

- Perform a matrix titration of forward and reverse primer concentrations for the internal control (e.g., 50 nM, 200 nM, 400 nM) while keeping the target primer concentration constant, and vice versa [47].

- Select the concentration combination that yields the lowest Ct value, the highest amplification efficiency, and a single, specific peak in the melt curve for both the target and internal control [47].

Optimization of Annealing Temperature (Ta):

- Using the optimized primer concentrations, run a gradient PCR with annealing temperatures ranging from 55°C to 65°C [47].

- The optimal Ta is the highest temperature that produces the lowest Ct value and a single, sharp melt curve peak for both the target and internal control, indicating specific amplification [47].

Validation of Reaction Efficiency:

- Prepare a standard curve using a serial dilution (e.g., 5-log range) of a known template for both the target and internal control genes.

- Amplify the dilution series using the optimized protocol. The reaction is considered efficient if the slope of the standard curve is between -3.1 and -3.6, corresponding to an efficiency of 90-110% [47] [27].

Co-amplification and Data Analysis:

- Run the final optimized assay with test samples, including no-template controls (NTCs) to check for contamination [12].

- Analyze the amplification and melt curves. The internal control should amplify consistently across all valid samples with a characteristic Tm. The target gene is quantified relative to the internal control to account for sample-to-sample variation [49].

Internal Control Integration Workflow

The diagram below outlines the logical workflow for integrating an internal control into a SYBR Green qPCR assay.

Research Reagent Solutions

The table below lists key reagents and materials essential for developing and running a robust SYBR Green qPCR assay with an internal control.

| Item | Function & Importance |

|---|---|

| Hot-Start DNA Polymerase | Reduces non-specific amplification and primer-dimer formation by remaining inactive until the high-temperature denaturation step [12] [47]. |